Chassis Offers Potential for Fuel Savings

The chassis system is defined as all of the parts in the tractor that carry the cab, hood, and powertrain. This includes frame rails, cross-members, axles, fuel tanks, battery boxes, etc. Although generally not an area for significant fuel efficiency options, new technologies are emerging.

Chassis Technologies

Lightweighting – Trailer

Emissions regulations combined with fuel economy features and driver amenities on today’s commercial vehicles have added 1,000 lbs. to the typical Class 8 truck.

Certain fleets like bulk haulers value weight savings more than other segments of the market. To understand the true benefits of reducing vehicle weight, fleets should look beyond fuel economy improvement to freight efficiency gains—the ability to use fewer trucks to carry the same amount of payload.

Fleets can save 2,000 lbs. by investing to a limited degree in lightweighting and as much as 4,000 lbs. with an aggressive investment. Lightweighting can take place in various areas of the tractor and trailer including the powertrain, axle suspensions, wheel ends, drive shaft, frame, 5th wheel, and more.

To learn more, download the Lightweighting Confidence Report.

6×2 Axles

Fleets switching their tractors to 6×2 axle configurations could realize a 2.5% fuel reduction, among other benefits. Since the original Confidence Report on 6×2 axles issued in January 2003 , 6×2 adoption among North America long-haul fleet has increased from approximately 2% to 4–5% in 2016. However, many fleets still view them as a niche offering suited for the southern region of the U.S.

Factors that have contributed to the limited adoption of 6×2 axles include: low fuel prices, higher tire wear, driver perception, residual value, and improved efficiency of 6×4 axles.

However there is reason for optimism with 6×2 technology. Through a combination of best practices and adoption of complementary technologies, fleets have found that 6×2 axles work for their application and are benefitting from the improved fuel consumption.

“Today’s emission-controlled engines are heavier. I will need the weight savings of a 6×2 to offset some of that increased weight.”

– Fleet Owner

Benefits

Fuel Efficiency

6×2 axles offer a 2.5% reduction in fuel use, with our study participants enjoying fuel economy improvements from 1.6% to 4.6%

Weight

6×2 axles offer significant weight reductions because a tag axle weighs less than a driven axle. In addition, the full configuration involves removing the inter-axle differential and associated inter-axle driveline components, as well as one differential gear set. A small amount of weight is added back in for load shifting and anti-spin measures. Overall weight reduction is in the 400-450 lb. range.

Cost Neutrality

Including all load shifting and electronics, 6x2s are on a par with 6×4 axles

Maintenance

The fact that the 6×2 configuration allows for a reduction in the total number of driveline components should lead to an overall reduction in maintenance costs. There should be less vibration complaints and fewer U-joint lubes. Overall savings is estimated at $100 per year.

Stability Improvement

An overlooked benefit of 6×2 axle technology is that it might give the truck additional stability and control when operating in slippery or poor road conditions. With a 6×2 configuration, the tag axle cannot spin out because it is not powered by the engine. This means there will be some level of lateral force available to keep the vehicle stable on its desired path, reducing the potential for a jackknife event initiated by wheel spin.

Challenges

Traction

The biggest concern surrounding 6×2 axles is loss of traction or tractive effort. Many of the situations where traction loss may be noticed with a 6×2 system are situations that should be avoided by vehicles no matter what the axle configuration:

- Deep snow

- Deep loose gravel

- Heavy ice

- Parking lots full of pot holes

Traction shortcomings of 6×2 axles can be mitigated with the use of load shifting technologies to increase weight on the drive axles at low speeds. The concern about traction is perceived to be a bigger challenge than it actually is.

Tire Wear

Fleets running early versions 6×2 tag axle configurations experienced accelerated wear on their drive tires vs. the same tires used on conventional 6×4 tractor tandems. Reported decreases in tire life range from 50–70% of the wear life on a 6×4 (i.e., one third to one half tire life vs. an equivalent 6×4).

Some tire manufacturers recently expanded their recommendations on the way 6×2 vehicles should be equipped to mitigate tire wear.

Driver Acceptance

Switching to a truck equipped with 6×2 axles will require some driver training. However, the newer traction control and automated load transfer systems remove a great deal of the concern about proper operation of a 6×2 truck from the driver.

Resale Value

There is no clear-cut view of the effects a 6×2 configuration will have on a vehicle at resale. Fleets that have embraced 6×2 technology indicated that they have buyers interested in purchasing their used trucks. Others believe that 6x2s will sell for upwards of $3,000 less than a comparable 6×4 tractor.

The common belief is that the resale value of 6×2 is rising, as the technology is better understood.

2014 Report

Technology Description

The study team identified three generations of 6×2 axles

- Generation I: 6×2 with tag axles, no load-shifting technology, and manual differential locks

- Generation II: 6×2 with tag axle, manual or automated load shifting, traction control, engine parameters adjusted to reduce low speed, clutch engagement, and engine brake torque

- Generation III: 6×2 with liftable pusher axle, automatic load sensing/load shifting, traction control, and engine parameters to limit low speed/brake torque

Available Systems

| ManufacturerManufacturer | Model | Type | Introduced | Advertised Weight Savings | Compatible System |

|---|---|---|---|---|---|

| Daimer Trucks NA | Detroit 6×2 | Tag | 2014 | Up to 400 lbs. | Wabco ECAS |

| Dana | Spicer Econotrek | Tag | 2013 | Up to 400 lbs. | Bendrix eTrac |

| Hendrickson | OPTIMAAX | Liftable Pusher | 2014 | Up to 400 lbs. | Hendrickson Optimaax |

| Mack | 6×2 with Lifting Pusher | Liftable Pusher | 2015 | Up to 400 lbs. | Mack |

| Meritor | Fuellite/Fuellite + | Tag | 2013 | Up to 400 lbs. | Wabco ECAS |

| Volvo | Adaptive Loading | Liftable Pusher | 2015 | Up to 400 lbs. | Volco |

Common Fleet Strategies

To achieve the best fuel economy with 6×2 axles, fleet purchase them with these other components:

- Single wide-base tires on the drive axle

- Ribbed low-rolling resistance wide-base trailer tires on the tag axle

- A direct-drive transmission

- A gear fast, run slow rear-axle ratio approaching 2.50 and filled with low-viscosity synthetic lube

Tire manufacturers have recently expanded their recommendations on the way 6×2 vehicles should be equipped.

| Position | NACFE Recommendation |

|---|---|

| Steer | Choose steer tires based on current normal selection. The exception may be for fleets testing liftable 6×2 axles (covered later in this report) that wish to increase front axle capacity. |

| Drive | Continue with the same drive tires as currently using on 6×4. A switch from a low-fuel tire to a mileage tire increases wear life but comes with an increase in fuel consumption that can overcome the benefit of 6x2s and is therefore not recommended without a careful analysis of the net impact. |

| Free-rolling | A retreaded trailer tire will likely have the lowest cost of ownership and maintain the fuel consumption benefit of a 6×2. As an alternative, fleets may choose to to use the same tires as on the driven axle although fleets should be aware that this can offset up to half the fuel savings. Drive tires on a free-rolling axle may experience uneven tire wear. Tire rotation is highly recommended. |

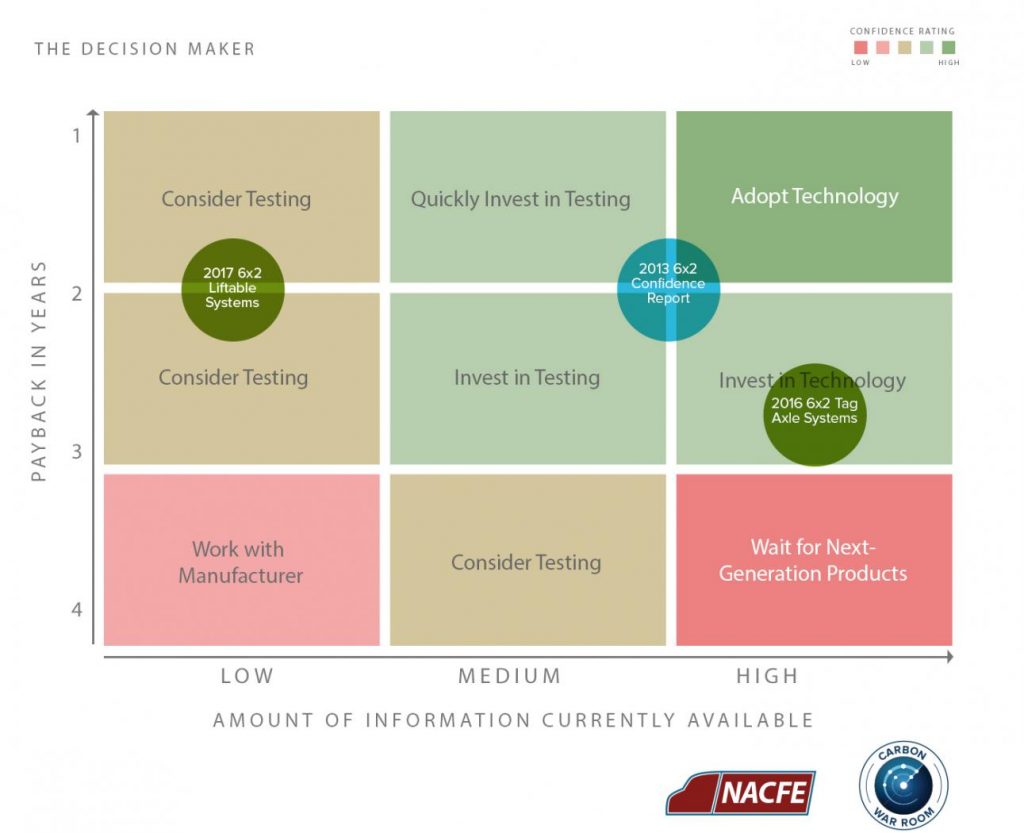

Decision-Making Tools

The study team developed a tool to help fleets in making their decision about 6×2 Axles. The Decision Maker is used to inform fleets of the study team’s confidence in the technology being studied vs. the payback a fleet should expect to receive from the technology.

Conclusions

Major study conclusions include:

- Drive tire wear on 6x2s will not achieve parity with 6x4s.

- Fleets that take a systemwide approach and implement the full Generation II “package,” including load-shifting technology, traction control, and engine parameters to limit torque in low gear, at clutch engagement, and under engine braking, have a much better chance to realize the ROI potential of 6x2s.

- Good and consistent driver communication and training is critical with this technology.

- The baseline (traditional 6×4 systems) is also improving. High-efficiency drive axles reduce the potential efficiency gains of a 6×2 system, albeit at a greater cost.

- Residual values for 6x2s remain a problem.

Cite Our Research

Liftable 6×2 Axles

Liftable pusher axles are the newest variation of 6×2 axles. They are suitable for fleets with diminishing loads where the full carrying capacity of a tandem axle is not needed all the time.

When operating in the down position, a liftable system performs like a conventional 6×2 system, with one drive axle and one free-rolling axle. When the full capacity of the tandem is no longer needed, the pusher axle is retracted off the road surface.

An additional 1% fuel economy improvement over non-lifting 6×2 systems is possible with liftable 6x2s.

Benefits

- Fuel Savings of 1% over traditional 6x2s.

- Better traction in certain situations through positioning of the drive axle behind the fifth wheel.

- Improved tire life on the free-rolling axle tires as well as other tires.

- Improved drivability due to the axle in the up position giving the truck an effective longer wheel base.

- Lower tolls since tollways typically charge by the axle

- Improved fleet image by providing a visible cue to the fleet’s commitment to improved fuel economy.

Challenges

- Increased cost and weight. The pusher axle requires a more expensive drop center axle.

- Additional component costs. Some fleets spec a heavier capacity front axle along with higher rated kingpins, bushings, and shock absorbers, plus heavier front suspension components and higher capacity tires.

- Legal restrictions. Utah does not allow liftable axles that are not steerable and most of Canada has restrictions.

- Not for all duty cycles. They are best suited for fleets with diminishing loads where the full carrying capacity of a tandem axle is not needed all the time.

- Unsure of residual value. As a very recent development, there is no residual value comparison available.

Common Fleet Strategies

Driver training and understanding of liftable 6x2s is critical.

Training needs to focus on:

- Helping drivers understand how the system functions

- The best way to handle liftable 6x2s in challenging conditions

- Techniques for handling poor traction situations

Fleets must implement a thorough communications and training plan to offset such biases. Major points that should be addressed include:

- A more efficient fleet is at an advantage over its competitors, which is a benefit to all employees. Technologies that the industry has not yet widely adopted, such as 6x2s, helps build that advantage.

- There is no evidence that 6x2s are less safe. Fleets that have implemented 6x2s report no safety issues. In fact, many believe they are more stable in slippery highway conditions.

- Traction issues can be addressed with the right combination of training and technologies including load shifting, traction control, and locking differentials.

Available Systems

Inn 2015 Volvo Trucks North America rolled out its Adaptive Loading product. The Volvo-driven technology developed with Link Manufacturing drives the rear axle in the tandem thereby making the front axle free. An electronically controlled axle lift for this forward axle offers load biasing in poor traction or actual lifting of the free rolling pusher axle clear of the pavement for additional fuel savings over those achieved with the regular 6×2 configurations.

Mack Trucks introduced the same product under the Lifting Pusher Axle name.

Hendrickson Truck Commercial Vehicle Systems’ originally announced the OPTIMAAX system in 2014 as a 6×2 solution with a liftable axle in the forward tandem position. Hendrickson has since refined the OPTIMAAX and will announce the launch OEM in 2017. A Hendrickson developed controller will manage the lift function as well as load biasing for traction. The system is expected to provide performance and benefits similar to Volvo’s Adaptive Loading with the added flexibility of availability at multiple truck OEMs.

Conclusions

Major study conclusions include:

- Drive tire wear on 6x2s will not achieve parity with 6x4s.

- Fleets that take a system-wide approach and implement the full Generation II “package” including load shifting technology, traction control, and engine parameters to limit torque in low gear, at clutch engagement, and under engine braking have a much better chance to realize the ROI potential of 6x2s.

- Good and consistent driver communication and training is critical with this technology.

- The baseline (traditional 6×4 systems) is also improving. High-efficiency drive axles reduce the potential efficiency gains of a 6×2 system albeit at a greater cost.

- Residual values for 6x2s remain a problem.

To learn more, download the 6×2 Axle Update Confidence Report.

Lightweighting

Emissions regulations combined with fuel economy features and driver amenities on today’s commercial vehicles have added 1,000 lbs. to the typical Class 8 truck. Certain fleets like bulk haulers value weight savings more than other segments of the market.

To understand the true benefits of reducing vehicle weight, fleets should look beyond fuel economy improvement to freight efficiency gains—the ability to use fewer trucks to carry the same amount of payload. Fleets can save 2,000 lbs. by investing to a limited degree in lightweighting and as much as 4,000 lbs. with an aggressive investment. Lightweighting can take place in various areas of the tractor and trailer including the powertrain, axle suspensions, wheel ends, drive shaft, frame, 5th wheel, and more.

Benefits

Fuel Savings

0.5% to 0.6% for every 1000 lbs. of weight reduction

Increased Freight Efficiency

Every pound of weight taken off the truck translates to another pound of payload that that the truck can legally carry

Driver Retention

Lighweighting makes it possible to spec driver amenities that add weight

Additional Fuel Efficiency Technology

Lighweighting makes it possible to spec other fuel efficiency technologies like aerodynamic devices and idle reduction products

Regulatory Compliance

A variety of regulations impact vehicle weight, lightweighing helps fleets comply with those regulations.

Sustainability

Lightweighting can reduce the number of trucks needed to haul the same amount of freight which is a major sustainability gain.

Challenges

Upfront Costs

The upfront cost to save 4,000 lbs. of weight does not offer an attractive payback, unless the duty cycle is payload limited.

Negative Impacts On Resale Value

Things like 13-liter engines, short and/or flat topped sleepers, 6×2 axles, other de-contenting, and less fuel tank capacity result in a lower resale value

Higher Maintenance Costs

Components may not be as robust and may be damaged more easily

Ability to Take Advantage

It is difficult to determine how much additional revenue and/or lower operating costs will be guaranteed

Redundant Product Testing

Time to market for lightweighting features is long in part because of redundancies in product testing.

Common Fleet Strategies

Only bulk carriers—representing 2% of the industry—operate at the 80,000 lb. limit nearly all the time. These fleets are willing to pay $6 to $11 up front cost per pound of weight saved. The majority of bulk haulers have already invested in lightweight technologies. About 10% of the trucks on the road—primarily reefers and some dry vans with dedicated routes—gross out on 10% of their trips. These fleets are willing to pay $2 to $5 per pound of weight saved. The other 88% of the trucking industry are dry van units that rarely travel (only 2% of the time) at maximum weight. These fleets are willing to pay $0 to $2 per pound of weight saved.

What People Are Saying

“The benefits of lightweighting are centered on payload — to carry more freight, or to offset the weight of other features added to the tractor and trailer.”

– Andrew Halonen, NACFE Lightweighting Consultant

“Lightweighting makes sense in a wide variety of applications when it is looked at not only in terms of better fuel economy but also improved freight efficiency.”

– Mike Roeth, NAFCE Executive Director

“If you’re not careful, the weight of these newer trucks will get away from you. In this industry, weight costs. Being able to shave off 2,000 lbs. on the base tractor equals profit — plain and simple.”

– Jamie Hagen, Owner and Truck Driver, Hell Bent Xpress LLC

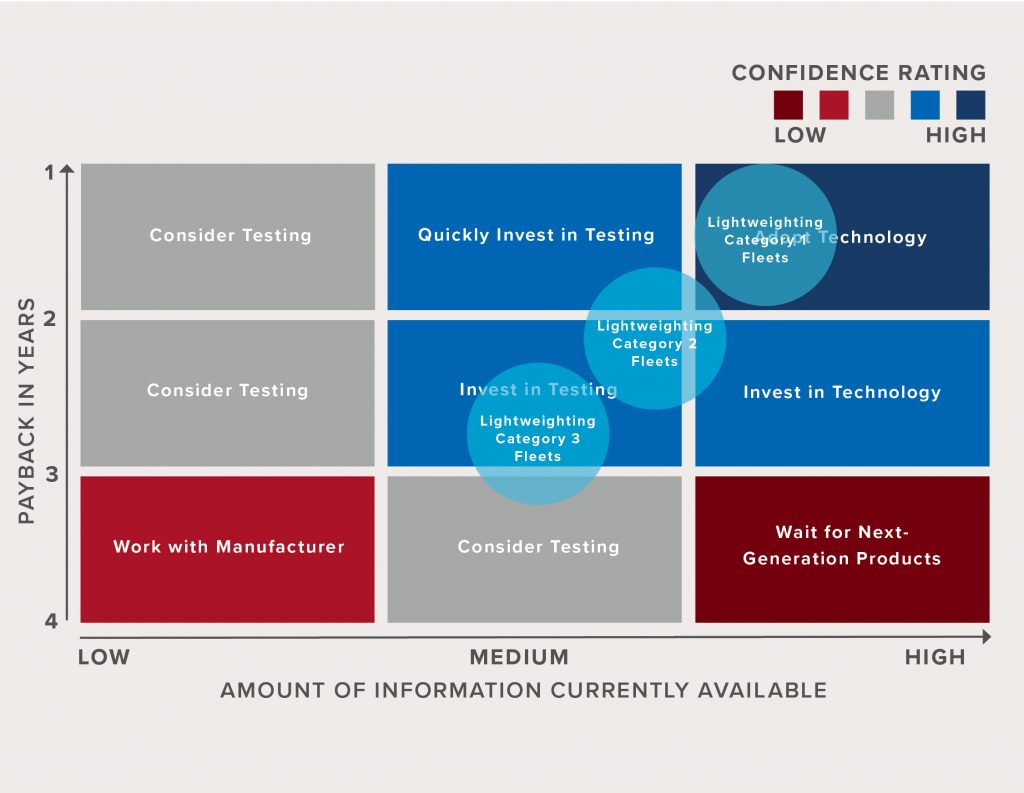

Decision-Making Tools

NACFE developed a tool to assist fleets in evaluating lightweighting. The Confidence Matrix shows how confident NACFE is in the adoption case for lightweighting.

Conclusions

- Through surveys conducted for this Confidence Report, the trucking industry confirmed the following trends:

- Tractor and to some degree trailer weights have increased,

- Freight is becoming denser, and

- Shippers are loading more pallets per trailer.

- Currently, the market can be divided into three categories with respect to its weight sensitivity and the percent of time that fleets are requested to gross out.

- Category 1: Trucks that currently travel at the 80,000-lbs. limit at some point along nearly 100% of their routes. This represents a small percentage of the industry (about 2%). This segment consists of bulk carriers.

- Category 2: Trucks that are loaded to the maximum weight (gross out) on a minority, perhaps 10%, of their trips. This represents about 10% of the trucks on the road, mostly refrigerator units but also some dry van routes.

- Category 3: Dry van units that rarely (2% of the time) or never travel at maximum weight, either because they are filled to maximum volume (cube out) before they gross out, or simply because their routes and cargo patterns are not conducive to traveling full. About 88% of the trucking industry falls into this category.

- NACFE finds that over the next five to 10 years and in light of these trends, shippers will request that Category 2 and Category 3 trucks double the percent of time they gross out, to 20% of the time for Category 2 and 4% of the time for Category 3.

- In order to meet these trends head-on and accommodate the heavier, denser freight, Category 2 and 3 fleets will have two options — add more trucks to the road, or explore lightweighting so that at least some of their trucks will be able to carry more freight.

- Lightweighting is by far the better option. Along with improving the overall freight efficiency of a fleet, lightweighting is a good investment because it opens the door for the adoption of additional beneficial technologies that might otherwise make a truck unacceptably heavier than it currently is.

- Both steel and aluminum wheels have dropped 5 lbs. each since the original study.

Recommendations

The study team developed the following recommendations:

- Above all, this report recommends that Category 2 and even Category 3 fleets begin to explore and spec lightweighting technologies in order to improve freight efficiency in the face of current industry trend. By doing so, they may even produce economies of scale that bring down the upfront cost of these technologies, while perhaps opening up new options for Category 1 fleets to adopt technologies that are currently too expensive.

- Another recommendation to bring down costs is for the industry to collaborate in order to address current redundancy in the development, testing, and product availability cycle among product developers, tractor-trailer integrators, and fleets.

- Finally, lightweighting for freight efficiency is a critical component of fuel efficiency, as it will facilitate the adoption of additional fuel efficiency technologies. Fleets should spec lightweighting options together with their other efficiency choices.

Cite Our Research

4×2 Tractors

NACFE recommends 4x2s for duty cycles that allow for the lower load capacity.

For duty cycles with lower loads, a single rear axle may improve efficiency by removing one axle and lowering tire rolling resistance. Commonly called single-axle tractors, 4×2 tractors lower fuel consumption by having one less axle and one less set of tires. These modifications reduce friction and tire rolling resistance on the road surface, thereby reducing fuel use. 4×2 tractors are less costly, but are limited to routes with lighter weight freight.

We are not planning a report on 4×2 axles, but may consider them for future evaluation. For more information, contact your tractor builder.

Benefits

Fuel Savings

Removing one axle also removes tires which lowers tire rolling resistance and therefor leads to fuel savings.

Lower Cost

One less axle and one less set of tires will cost fleets less money.

Less Maintenance

Challenges

Possible Limitations to Trailer Use

Application Limited to Certain Lightweight Duty Cycles

Synthetic Axle Lubricant

Synthetic lubes/oils maintain their viscosity at low and high temperatures and have less friction and heat, which promotes energy efficiency and fuel economy. Significant improvements have been made to synthetic lubricants and the increase in scale has contributed to lower costs.

Benefits

Fuel Savings

Synthetic axle lubes maintain their viscosity at low and high temperatures and have less friction and heat, which promotes fuel efficiency.

Stability at High Temperatures

Less Maintenance

Better Protection & Less Wear

Challenges

Cost of Technology

Synthetic lube costs more.

Availability on the Road

Synthetic lube can be harder to find when the truck is away from its home location.

Two-Speed / Modulating Cooling Fan

Cooling fans located behind the radiator draw cool air across the radiator and into the engine compartment. The traditional fans are simple on or off devices. In its simplest form, the vehicle cooling system consists of an engine-driven water pump that moves coolant through a series of passages to keep the engine components cool from the extreme heat generated through combustion. This heat is then rejected to the atmosphere through the vehicle radiator/cooling fan system.

There are a number of options available in the marketplace that help reduce fuel consumption due to the cooling fan. They include 2-speed/modulating fan drives and fully modulating fan drives. Depending on the application, savings for a 2-speed/modulating cooling fan would be perhaps one-third of the fuel burned due to fan operation.

Some fully modulating fans are available to further reduce the fuel consumption during fan-on operation. The control system for these fans can vary the speed from 0 to full on and add only enough fan speed to meet the necessary cooling requirements of the vehicle.

It is important to note that cooling fans typically consume 0.2–0.4% of the truck’s fuel to perform their function, so any fuel economy gains from new technology will be modest.

Benefits

Reduced Power Consumption

Less Fan Clutch & Belt Wear

Challenges

Increased Cost

Increased Complexity

Increased Weight/Size

To learn more, download the Variable Engine-Driven Accessories Confidence Report.

Clutched Air Compressor

Traditional air compressors for brakes turn constantly and pump air when necessary. The air pressure is monitored and controlled typically by a governor valve that maintains the pressure between two set limits. The upper pressure is normally termed the “cut-out” pressure and the lower pressure limit is called the “cut-in” pressure, typically set at 130 psi and 110 psi respectively. The ratio of time at cut-out to cut-in is called the duty cycle, and this can vary between 10–30% depending on the type of operation and the amount of air the system consumes.

New clutched air compressors eliminate the robbing of engine power when the air tanks are already at required pressure levels. These designs typically have a multi-plate clutch arrangement mounted on the input drive to the compressor. When the air system pressure reaches its cut-out pressure, in addition to a signal sent to the compressor cylinder-head, there is also a signal sent to the clutch, which essentially disengages the compressor from the gear drive and therefore minimizes power consumption when the compressor is not pumping. When the system air pressure drops, the clutch is re-engaged and the compressor starts to deliver air again.

It is important to note that air compressors typically consume 0.25–0.8% of the truck’s fuel to perform their function, so any fuel economy gains from new technology will be modest.

Benefits

Reduce Power Consumption When Off-Load

Less Compressor Wear

Lower Oil Carryover

Challenges

Increased Cost

Increased Weight/Size

Additional Maintenance

To learn more, download the Variable Engine-Driven Accessories Confidence Report.

Dual Displacement Power Steering Pump

Power steering pumps typically run all the time to handle worst-case needs of low-speed vehicle turning and maneuvering. Virtually all heavy-duty trucks have power steering systems to assist with the turning of the vehicle when necessary.

The power steering system consists of a hydraulic engine-driven power steering pump, a steering gear, control valves to route the hydraulic fluid depending on the direction of the turn, a small fluid reservoir, and hydraulic hoses to route fluid to the appropriate components. In addition, a fluid cooler is sometimes required to keep the hydraulic fluid in the proper temperature range. The power steering pump turns and generates pressure/flow any time the engine is running.

New systems take into account the fact that line-haul tractors spend the vast majority of their operating hours going nearly straight down a highway when little steering effort is necessary. The dual displacement power steering pump works by using the full displacement available when the engine is at a low speed. Once the engine/pump speed is sufficient, the dual displacement power steering pump automatically switches to the pump with smaller displacement that takes less horsepower to turn.

It is important to note that power steering pumps typically consume 0.3–0.6% of the truck’s fuel to perform their function, so any fuel economy gains from new technology will be modest.

Benefits

Fuel Savings

Lower Power Consumed

Challenges

Not Available from any Truck OEMs as of March 2017

Increased Cost

Increased Complexity

Reliability Concerns

Increased Maintenance Costs

To learn more, download the Variable Engine-Driven Accessories Confidence Report.

Smart Air Dryer

The air dryer removes moisture from the compressed air for the brakes. The majority of air systems are controlled by a governor valve—a mechanical valve that switches between two preset pressures. No consideration is given to the engine driving mode or the most efficient time to draw power from the engine to drive the compressor.

With a smart air dryer, the air pressure in the reservoirs is monitored by a pressure sensor, and in addition, the vehicle CAN bus is monitored to determine the driving state of the vehicle/engine. The system determines when the vehicle/engine is in an over-run or coasting phase and operates the compressor most efficiently during these phases. New smart air dryers assist in optimizing when to run the air compressor and purge the moisture from the air system.

Benefits

Reduced Power Consumption

Air System Prognostics

Ability to Determine Air Cartridge Replacement Cycles

Better Air Compressor Utilization

Challenges

Increased Cost

Increased Weight/Size

Additional Complexity

To learn more, download the Variable Engine-Driven Accessories Confidence Report.

Hybrid Electric Powered Axle

A 6×4 chassis can now have both an engine driven axle and an electrically driven axle. The regenerative braking can not only save on brake wear, the energy can be captured in situations where additional power is beneficial such as vehicle launch or steep/lengthy inclines to decrease fuel consumption. Effectively the vehicle is a 6×2 when normal efficient operation is desired and becomes a 6×4 when it is most beneficial.

Benefits

Fuel Savings

Available Power

Challenges

Weight

Cost

Introduction & Rationale

Formula One race cars utilize regenerative braking as do numerous models of electric and hybrid passenger cars. An electric drive axle is used for the rear tractor axle in this strategy. During downhill runs and during braking situations, the axle powers an electric motor-generator which stores the generated electric power in a lithium ion battery pack. When appropriate for power to be applied via this axle the process is reversed to keep the diesel engine operating most efficiently.

Available Systems

A few suppliers have developed electric axles and these systems are now in validation. One supplier provides a complete solution which combines their electric axle with the battery, an electric AC system and the controlling software.