6×2 Axles

Fleets switching their tractors to 6×2 axle configurations could realize a 2.5% fuel reduction, among other benefits. Since the original Confidence Report on 6×2 axles issued in January 2003 , 6×2 adoption among North America long-haul fleet has increased from approximately 2% to 4–5% in 2016. However, many fleets still view them as a niche offering suited for the southern region of the U.S.

Factors that have contributed to the limited adoption of 6×2 axles include: low fuel prices, higher tire wear, driver perception, residual value, and improved efficiency of 6×4 axles.

However there is reason for optimism with 6×2 technology. Through a combination of best practices and adoption of complementary technologies, fleets have found that 6×2 axles work for their application and are benefitting from the improved fuel consumption.

“Today’s emission-controlled engines are heavier. I will need the weight savings of a 6×2 to offset some of that increased weight.”

– Fleet Owner

Benefits

Fuel Efficiency

6×2 axles offer a 2.5% reduction in fuel use, with our study participants enjoying fuel economy improvements from 1.6% to 4.6%

Weight

6×2 axles offer significant weight reductions because a tag axle weighs less than a driven axle. In addition, the full configuration involves removing the inter-axle differential and associated inter-axle driveline components, as well as one differential gear set. A small amount of weight is added back in for load shifting and anti-spin measures. Overall weight reduction is in the 400-450 lb. range.

Cost Neutrality

Including all load shifting and electronics, 6x2s are on a par with 6×4 axles

Maintenance

The fact that the 6×2 configuration allows for a reduction in the total number of driveline components should lead to an overall reduction in maintenance costs. There should be less vibration complaints and fewer U-joint lubes. Overall savings is estimated at $100 per year.

Stability Improvement

An overlooked benefit of 6×2 axle technology is that it might give the truck additional stability and control when operating in slippery or poor road conditions. With a 6×2 configuration, the tag axle cannot spin out because it is not powered by the engine. This means there will be some level of lateral force available to keep the vehicle stable on its desired path, reducing the potential for a jackknife event initiated by wheel spin.

Challenges

Traction

The biggest concern surrounding 6×2 axles is loss of traction or tractive effort. Many of the situations where traction loss may be noticed with a 6×2 system are situations that should be avoided by vehicles no matter what the axle configuration:

- Deep snow

- Deep loose gravel

- Heavy ice

- Parking lots full of pot holes

Traction shortcomings of 6×2 axles can be mitigated with the use of load shifting technologies to increase weight on the drive axles at low speeds. The concern about traction is perceived to be a bigger challenge than it actually is.

Tire Wear

Fleets running early versions 6×2 tag axle configurations experienced accelerated wear on their drive tires vs. the same tires used on conventional 6×4 tractor tandems. Reported decreases in tire life range from 50–70% of the wear life on a 6×4 (i.e., one third to one half tire life vs. an equivalent 6×4).

Some tire manufacturers recently expanded their recommendations on the way 6×2 vehicles should be equipped to mitigate tire wear.

Driver Acceptance

Switching to a truck equipped with 6×2 axles will require some driver training. However, the newer traction control and automated load transfer systems remove a great deal of the concern about proper operation of a 6×2 truck from the driver.

Resale Value

There is no clear-cut view of the effects a 6×2 configuration will have on a vehicle at resale. Fleets that have embraced 6×2 technology indicated that they have buyers interested in purchasing their used trucks. Others believe that 6x2s will sell for upwards of $3,000 less than a comparable 6×4 tractor.

The common belief is that the resale value of 6×2 is rising, as the technology is better understood.

2014 Report

Technology Description

The study team identified three generations of 6×2 axles

- Generation I: 6×2 with tag axles, no load-shifting technology, and manual differential locks

- Generation II: 6×2 with tag axle, manual or automated load shifting, traction control, engine parameters adjusted to reduce low speed, clutch engagement, and engine brake torque

- Generation III: 6×2 with liftable pusher axle, automatic load sensing/load shifting, traction control, and engine parameters to limit low speed/brake torque

Available Systems

| ManufacturerManufacturer | Model | Type | Introduced | Advertised Weight Savings | Compatible System |

|---|---|---|---|---|---|

| Daimer Trucks NA | Detroit 6×2 | Tag | 2014 | Up to 400 lbs. | Wabco ECAS |

| Dana | Spicer Econotrek | Tag | 2013 | Up to 400 lbs. | Bendrix eTrac |

| Hendrickson | OPTIMAAX | Liftable Pusher | 2014 | Up to 400 lbs. | Hendrickson Optimaax |

| Mack | 6×2 with Lifting Pusher | Liftable Pusher | 2015 | Up to 400 lbs. | Mack |

| Meritor | Fuellite/Fuellite + | Tag | 2013 | Up to 400 lbs. | Wabco ECAS |

| Volvo | Adaptive Loading | Liftable Pusher | 2015 | Up to 400 lbs. | Volco |

Common Fleet Strategies

To achieve the best fuel economy with 6×2 axles, fleet purchase them with these other components:

- Single wide-base tires on the drive axle

- Ribbed low-rolling resistance wide-base trailer tires on the tag axle

- A direct-drive transmission

- A gear fast, run slow rear-axle ratio approaching 2.50 and filled with low-viscosity synthetic lube

Tire manufacturers have recently expanded their recommendations on the way 6×2 vehicles should be equipped.

| Position | NACFE Recommendation |

|---|---|

| Steer | Choose steer tires based on current normal selection. The exception may be for fleets testing liftable 6×2 axles (covered later in this report) that wish to increase front axle capacity. |

| Drive | Continue with the same drive tires as currently using on 6×4. A switch from a low-fuel tire to a mileage tire increases wear life but comes with an increase in fuel consumption that can overcome the benefit of 6x2s and is therefore not recommended without a careful analysis of the net impact. |

| Free-rolling | A retreaded trailer tire will likely have the lowest cost of ownership and maintain the fuel consumption benefit of a 6×2. As an alternative, fleets may choose to to use the same tires as on the driven axle although fleets should be aware that this can offset up to half the fuel savings. Drive tires on a free-rolling axle may experience uneven tire wear. Tire rotation is highly recommended. |

Decision-Making Tools

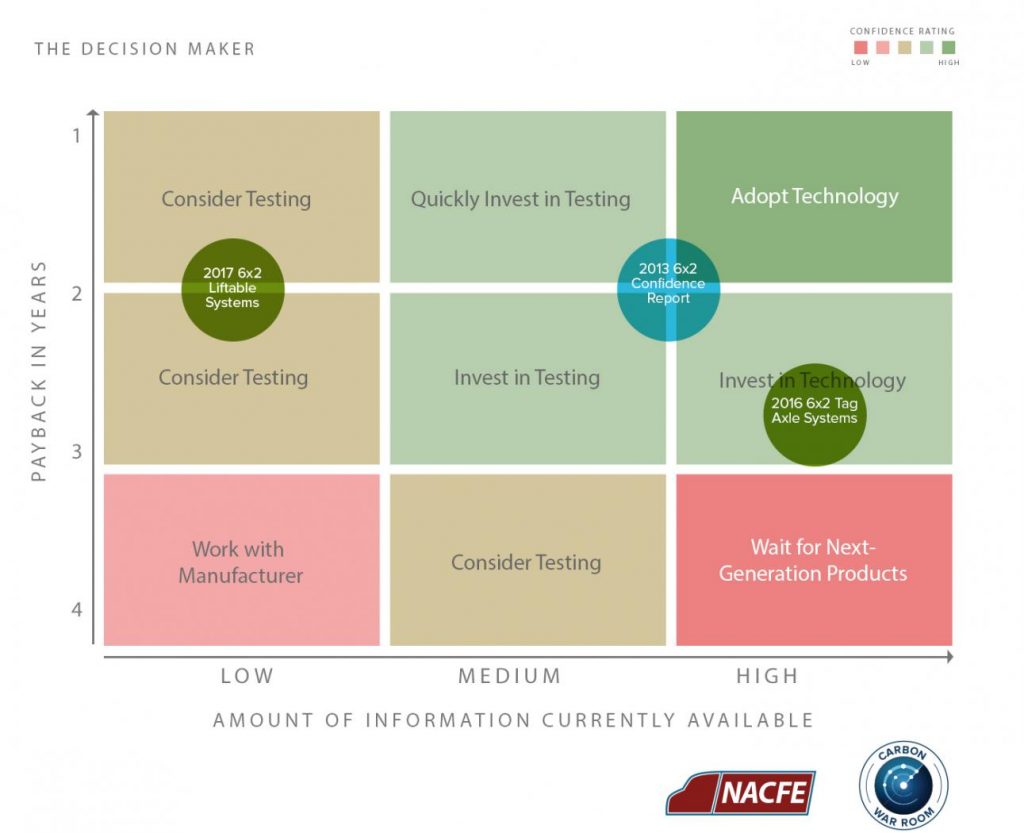

The study team developed a tool to help fleets in making their decision about 6×2 Axles. The Decision Maker is used to inform fleets of the study team’s confidence in the technology being studied vs. the payback a fleet should expect to receive from the technology.

Conclusions

Major study conclusions include:

- Drive tire wear on 6x2s will not achieve parity with 6x4s.

- Fleets that take a systemwide approach and implement the full Generation II “package,” including load-shifting technology, traction control, and engine parameters to limit torque in low gear, at clutch engagement, and under engine braking, have a much better chance to realize the ROI potential of 6x2s.

- Good and consistent driver communication and training is critical with this technology.

- The baseline (traditional 6×4 systems) is also improving. High-efficiency drive axles reduce the potential efficiency gains of a 6×2 system, albeit at a greater cost.

- Residual values for 6x2s remain a problem.