Simple Changes Can Lead to Big Fuel Savings

Some solutions do not require significant equipment or technologies, but are defined as operational practices. A few are included here and over time it is expected that more will be identified and defined in more detail.

Practices

Preventive Maintenance

All fleets need to maintain their vehicles to ensure safe and reliable performance, to avoid costly breakdowns and to allow vehicles to reach their maximum useful life. However, even a vehicle that is running safely and reliably may still enjoy substantial fuel economy savings from additional or more optimized maintenance.

Benefits

Fuel Savings

Fuel savings of between 5-10% can be achieved.

Improve Vehicle Reliability and Reduced Breakdowns

Well‐maintained trucks are less likely to have on‐road breakdowns; unscheduled repairs are the costliest and result in more downtime.

Increased Resale Value

Anecdotal evidence shows that buyers of used equipment are willing to pay more for a vehicle when the seller has records that prove maintenance was done on an ongoing basis. There is evidence that a well‐maintained truck, for which maintenance records are available, will bring more money at resale.

Enhanced Driver Safety and Satisfaction

Well‐maintained trucks are safer to operate. Given the worsening driver shortage, anything that can be done to improve driver satisfaction is a bonus for fleets, and drivers vastly prefer to drive trucks that don’t break down or otherwise suffer from performance issues.

Reduced CSA Violations & Fines

The overwhelming majority of CSA violations are in the Maintenance BASIC category, so it stands to reason that better maintenance will lead to fewer violations.

Challenges

Scheduling

Difficult to schedule maintenance service so it does not impact productivity.

Tracking/Ensuring Compliance

Difficult to know which vehicles have had their scheduled maintenance service and which still need to come into the shop.

Demonstrating Return on Investment

It can be difficult to prove that a change in maintenance caused a gain in fuel economy.

What Fleets Are Saying

When asked how strong they felt the link between maintenance practices and fuel economy was, 75% of survey respondents said they saw a strong or very strong link between the two.

We do consider the fuel economy benefits of maintenance when making decisions to invest in a more aggressive maintenance program, whether software, personnel, tools or equipment.

— A fleet manager

One fleet instituted a maintenance program that allows a truck to be diverted to a maintenance facility for evaluation if the vehicle’s MPGs decrease.

I believe there is a close correlation between maintenance and fuel economy, but my opinion may not be widely shared among my management peers.

— A fleet manager

Best Practices

- Start by reviewing OEM and component supplier recommendations.

- Consider using the Recommended Practices developed by The Technology & Maintenance Council.

- Perform maintenance on an on-going basis and in a consistent manner.

- Invest in technology that allows you to schedule and track maintenance compliance.

Decision-Making Tools

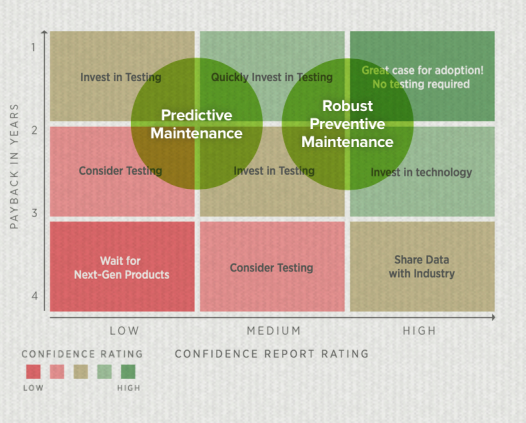

The study team developed a tool to help fleets in making their decision about electronically controlled transmissions. The Confidence Matrix is used to inform fleets of the study team’s confidence in the technology being studied vs. the payback a fleet should expect to receive from the technology.

Conclusions & Recommendations

- Fleet view maintenance as important, but tend to look at it as a means for reducing downtime rather than improving fuel economy.

- There are a variety of sources available to obtain information about the maintenance needs of various components.

- There is strong evidence that properly maintained trucks will enjoy improved fuel economy.

- Including information about the increased fuel economy of well-maintained trucks can make the ROI of an investment in maintenance technology, tools, bay space, technicians or software easier to sell across all levels of fleet management.

Two-Truck Platooning

Two-truck platooning is an emerging technology designed to boost fuel economy performance for tractor-trailers engaged in long- and regional-haul highway applications.

Platooning combines existing commercial vehicle safety technology with emerging vehicle-to-vehicle communications and autonomous vehicle control technology to electronically “tether” tractor-trailers together in a convoy formation at highway speeds.

Once a platoon of trucks is established, the vehicles, safety systems work in unison to draw the trucks together at significantly reduced following distances to overcome each vehicle’s inherent aerodynamic drag.

I’m hearing 3 to 5% fuel economy boost from platooning. The fuel economy benefits are pretty strong. That’s a lot at any fuel price per gallon.

– A Mid-Sized Fleet

Benefits

Fuel Savings Fuel savings depend on many factors. At a 40 – 50 ft. following distance directionally, the front truck can save 4% on fuel and the following truck can save 10%, giving an average of 7% (versus the two trucks not platooning).

The fuel savings of two-truck platooning is likely a 4% average savings over the two trucks in real-world operating conditions after accounting for traffic, terrain and time when equipped trucks will not be operating in a platoon.

Accelerates Adoption of Safety Equipment

Challenges

Payback

The payback for platooning is driven by many factors, including the upfront cost for the equipment, any subscription costs for platooning, the savings in fuel, the costs to mitigate any of the challenges, and the level to which the fleet is already investing in safety technologies.

Driver Acceptance

Drivers must learn, and become comfortable with, an entirely new operational dynamic behind the steering wheel.

Platoon Integrity

There is concern about how drivers will react if a passenger car moves into the gap between the platooning trucks.

System Security

There is concern about hacking of the communication system of the platooning trucks.

Amount of Viable Platooning Time

It is an open question whether platooning might be a viable option only a small percentage of the time and whether any fuel savings would justify the outlay in acquisition and operational costs.

Legislative Efforts & Public Awareness

Changes to traffic laws that reflect the impact this new technology will have on highway transportation need to be considered on both the state and federal levels.

Shared Fuel Savings

Reliability

Reliability of platooning technology systems remains unknown, as there is little field history on these systems.

Litigation

Imbedded in operating costs is a need to address the potential impact of litigation.

What People Are Saying

Comments about platooning center on things like the timeline for its implementation, fuel savings, following distances, driver acceptance, driver pay, cost, and platooning with other fleets.

I’m thinking 2018 to 2030 before we see platooning operations on the road. There are still way too many studies that have to be done on this subject.

— A Major Truckload Fleet Manager

It’s about finding the sweet spot with aerodynamic benefits for both the front and rear vehicles, but also spreading the gap somewhat gives the second driver more to look at and is less fatiguing.

— A Private Fleet Manager

We don’t think the cost will be as high as some groups are forecasting.

— A Technology Developer

The driving experience with platooning has been very similar to normal truck driving today.

— A Test Truck Driver

We’re not sure [about platooning with other fleets]. It will be our position initially that we will not platoon with anyone else.

— A Fleet Manager

While technology may support platooning quite well…I don’t see fleets willing to take the risk in our current environment with litigation.

— A Fleet Manager

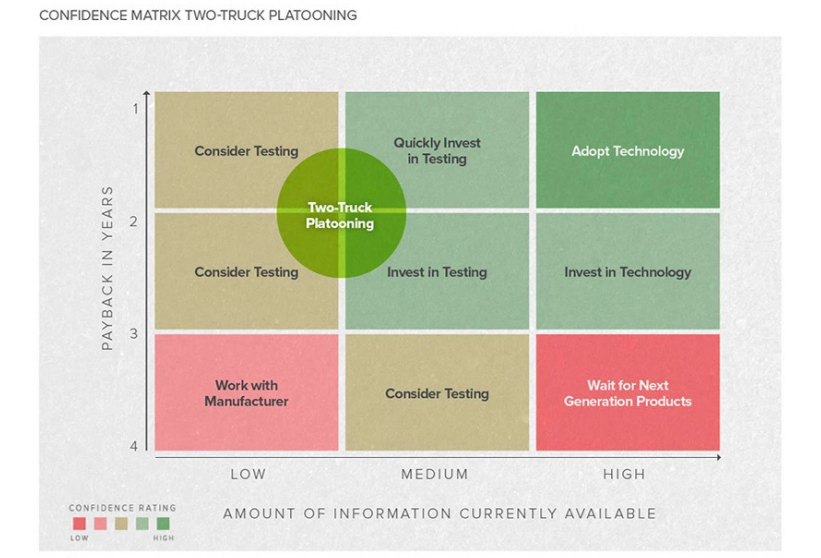

Decision-Making Tools

The study team developed a tool to help fleets in making their decision about two-truck platooning. The Confidence Matrix plots where the two-truck platooning choice falls in terms of available data on the technology and how quickly fleets should realize payback.

Conclusions

- The fuel savings of two-truck platooning is likely a 4% average savings over the two trucks in real-world operating conditions after accounting for traffic, terrain and time when equipped trucks will not be operating in a platoon.

- The bulk of the required technology is currently available and being purchased by many fleets.

- Intervals of 40 to 50 ft. will likely have sufficient payback for early adopting fleets and then shorter distances, with their higher fuel savings, can be implemented with product improvements.

- Two-truck platooning is not fully autonomous/driverless trucking and it is actually being improperly grouped with that concept.

- Driver stress will likely be less than perceived to date.

- Platooning will accelerate the adoption of other technologies such as collision avoidance and adaptive cruise control.

Limiting Speed

Speed limits set a given maximum speed for the truck. Lowering the truck speed will have significant fuel savings due to decreased aerodynamic drag and tire rolling resistance.

Some fleets allow higher speeds for limited periods of time such as for passing slower vehicles. Driver fuel economy bonuses oftentimes include time at cruise control speeds as a key determination of the level of cost savings shared with drivers.

A technology overview has been published, and a more detailed Confidence Report is not planned at this time, given the simplicity of the solution.

Benefits

Fuel Savings

Fuel savings result from reduced drag.

More Comfortable Driving, Less Passing

Potential Inclusion in Parameters

Challenges

Long Overall Trip

In an informal survey of large fleets, fleets reported that when they lowered their speed by about 5 mph (e.g. 68 to 63 mph) their daily trip times only increased about 18 minutes.

Reduction of Empty Miles

Freight efficiency is defined as the amount of freight hauled per gallon of fuel used, so the fuller the trailer the better overall efficiency. Many software management tools are available to help reduce empty miles by finding additional freight to haul given each fleet’s capabilities with routes, equipment, time, and other variables.

Trucking Efficiency is not currently planning any studies in this area, given the simplicity of the solution, but will consider with industry interest.

Benefits

Increased Income

By hauling more freight in a given vehicle, the fleet or owner/operator can increase income made with a vehicle.

Challenges

Difficulty Finding Additional Loads

Risk to Outbound Freight Times

Selection of Software Solutions

Driver Training

Drivers can impact fuel efficiency of a tractor-trailer by more than 20%, and training is a promising opportunity to improve the driver’s impact on fuel costs. This training can take the form of courses in a classroom, online training tools, or messages via phone or telematics systems to the truck, among others.

Benefits

Fuel Savings

Driver Retention

Challenges

High Industry Driver Turnover

Training Expenses

Driver Incentives

Many driver incentive strategies are being deployed by fleets to improve fuel economy and driver retention. Drivers can receive pay bonuses, per-mile pay increases, or prizes for attaining predefined fleet-wide efficiency goals or out-achieving other drivers.

Driver retention improves fuel economy increasing the effectiveness of almost all fuel efficiency technologies as the drivers are comfortable and trained in the specific equipment bought by that fleet. For fleets with low driver turnover, the value of driver training is improved since the drivers trained stay with the fleet.

Benefits

Fuel Savings

Driver Retention

Challenges

High Industry Driver Turnover

Perceptions of Unfair Metrics & Program Rules

Program Expenses

To learn more, download the Driver Coaching Aids Tech Overview.

In-Cab Behavior Notifications

The driver plays a critical role in the efficient operation of a commercial vehicle and can have a direct impact on fuel economy. Technologies are available to notify the driver of behaviors affecting fuel economy such as speed, idle time, fast accelerations, hard braking, improper cornering, and other factors.

Benefits

Notification to Driver of Unsafe Behaviors

Getting a real-time notification of unsafe driver behavior allows the driver to take immediate corrective action.

Safety Notifications (Some Systems)

Some systems will notify the driver if a collision is imminent.

Notification to Fleet Owner of Driver Behavior

Opportunity to Improve Training

In-cab behavior notifications can be used to improve driver training.

Challenges

Distraction for Drivers

In-cab notifications can be a source of distraction to drivers.

Driver Acceptance

Drivers may not like the “big brother” aspect of some systems.

To learn more, download the Driver Coaching Aids Tech Overview.

Routing Optimization

Freight efficiency is defined as the amount of freight hauled per gallon of fuel used, so the fuller the trailer the better overall efficiency. Out-of-route miles waste driving time and fuel, so managing out-of-route miles can save a significant amount of fuel and money.

Many software management tools are available to help fleets select the most efficient routes for their trucks and find additional freight to haul.

Trucking Efficiency is not currently planning any studies on routing optimization, but will consider conducting a study in response to industry interest.

Benefits

Fuel Savings

Out-of-route miles consume fuel unnecessarily.

Timeliness

Route optimization reduces time the driver spends lost, and saves time.

Challenges

System Implementation

Selection of Optimal Software Solution(s)

Coasting Before Braking

Implementation of coasting before engine braking means the engine brake will not activate immediately after the accelerator pedal is released. This allows the vehicle to coast until the service brakes are applied.

NACFE is not currently planning any studies on coasting before braking, given the simplicity of the solution, but would consider conducting a study in response to industry interest.

Benefits

Fuel Savings

Challenges

Driver Training

Parking

When the economy is doing well, the number of trucks on the road is at a very high level. Drivers of each of these vehicles need places to pull over for restrooms, mandatory 30-minute rest breaks, meals and in many cases a place to sleep safely.

Many shippers do not allow the vehicles to remain on their lots while drivers are sleeping. This places a large responsibility on the industry (and society) to have places to park, especially at night. Industry surveys indicate that half the drivers spend an hour or more per day seeking parking spots. That is a huge inefficiency in freight movement and a significant waste of fuel as well.

Benefits

Predetermined Parking Location

Allows more time for driving without the driver having to worry about the availability of a parking spot. This is also better use of fuel.

Challenges

Hours of Service

It is very likely that a driver may need to violate the hours of service rules while seeking a parking location if all the spots are taken in a given area. The other option of parking in an unsafe or non-designated spot for truck is not a good alternative. If the driver annotates their log that parking is full, they can use “personal conveyance” to continue driving to find a safe parking location.

Highway Rest Stops

As states face budget constraints, one area that gets hit is support of rest areas on the highways. Every time another rest stop is closed, dozens of trucks need to find new parking places for their mandatory rest periods.

System Cost

The infrastructure cost including a sensor system to determine the number of vacant spots or throughput of vehicles is not simple or inexpensive. A reservation system for a truck stop is not an inexpensive system to deploy and enforce as well.

Introduction & Rationale

The implementation of ELDs (Electronic Logging Devices) has created an environment in which it is critical for drivers to find parking before their Hours of Service have expired.

Available Systems

- Florida’s Department of Transportation Truck Parking Availability System (TPAS for I-4 & I-95)

- Pilot Flying J’s Prime Parking program myPilot app

- Travel Centers of America Reserve-It! on the TruckSmart app

- Truck Parking Information Management System (TPIMS): Indiana, Iowa, Kansas, Kentucky, Michigan, Minnesota, Ohio and Wisconsin (www.trucksparkhere.com)

- Trucker Path smartphone application

- Hotels4Truckers.com knows which hotels are equipped for truck parking, while requiring the driver to buy a room for the night

Telematics

Big data is taking hold in our society and its benefits are constantly growing. Even the trucking industry is using data to improve operational efficiencies. The fastest way to gather data from a truck fleet is through telematics, and it is also a fast way to get information back out to the drivers who control the tractors and trailers.

Benefits

Location

If piece of equipment has a live telematics system on-board it is easy to locate. This can improve accuracy and response times to downed trucks and help keep mobile technicians more accountable when being managed remotely.

Integrated Data

With the proper telematics system, existing fleet information systems for maintenance, back office systems, driver training and more need to be linked for optimized data sharing.

Customization

Fleets can create systems that meet their specific needs through the use of tools such as a Software Development Kits (SDKs) and Application Programing Interfaces (APIs).

Uptime

Telematics can provide fault codes directly and instantly to the fleet maintenance manager. Some fleets look at the fault code and have the driver exit the interstate for service and avoid a towing bill if the situation demands it.

Driver Coaching

Telematics allows a high level of two-way communications. The ability to measure more behaviors more rapidly enhances management’s ability to understand what is happening in real time. The capability to coach and send advice or performance scores to drivers while they are on the road makes feedback instantaneous.

Vehicle Health

Using the diagnostic data, fleets can reduce unscheduled vehicle downtime with more proactive maintenance, which can also lead to extending the life of the vehicle.

Fuel Efficiency

Many basic telematics solutions offer simple fuel monitoring tools to reduce unnecessary waste from idling and other factors.

Driver Safety

Most telematics solutions have some basic safety monitoring systems to monitor and report unsafe driver behavior like speeding, hard acceleration and hard braking.

Operational Efficiency

Many fleets rely on telematics solutions to help improve overall operational efficiency. By comparing the data collected across an entire fleet of vehicles, fleet managers can easily identify and compare individual and groups of drivers to determine where help is needed. Data analysis can also highlight issues with a particular make of vehicle or a group of vehicles to help guide specifications changes to future orders.

Enabler

Telematics forms the basis for many of the more advanced systems in trucking such as predictive cruise control, platooning and autonomous operation.

Challenges

Installation

Prewiring or retrofitting vehicles to integrate the telematics system can be anywhere from very easy to a time-consuming effort requiring interior disassembly and integration.

Upkeep

Like most any electronic devices, with telematics there are hardware and software updates that occasionally need to be made. That can be a challenge with a rolling fleet of vehicles.

Costs

Some telematics providers require customers pay for the telematics hardware (the part that connects to the vehicle) and a recurring monthly service charge. This service charge typically includes the cellular or satellite connection charges, which need to be discussed in detail prior to a purchase decision.

Introduction & Rationale

In detailed analysis of the Run on Less fuel economy demonstration, one of the conclusions was the need for telematics in fleet operations. There is a saying that “you can only manage what you can measure” and telematics is a primary path to accessing many different forms of measurements.

Definitions vary widely, but “telematics” refers specifically to systems that track the location (GPS) and onboard diagnostic data for vehicles. There are many more applications that rely on telematics data access (such as electronic logs), but these are not considered true telematics solutions.

Available Systems

Whatever the fleet’s need, it’s likely that sensors and a telematics system exists to provide a solution from watching trailer doors to watching the driver. Both satellite and cellular systems are in used in the industry.

Transportation-specific systems are available as solutions for trucks, buses, passenger cars, off-road equipment and more. Cellular systems are the most common and popular method of data transfer with wide coverage and high data rates. Satellite systems are still used in remote or very high priority areas.

Upfits & Retrofits

While much of NACFE’s information focuses on the “what”, to implement these solutions can require a lot of work on the “how” to make the transition to a new vehicle feature. If a feature is not offered on the vehicle configuration that you desire, there are other ways to obtain the desired product.

Features can be “upfit” at a customization center immediately after initial production. It is also common to “retrofit” a feature to a vehicle after it is in service. This is especially true when it comes to the addition of trailer skirts or automatic tire inflation systems on trailers.

Benefits

Fuel Economy

If a new feature shows promise and has a good ROI for your fleet, getting it installed across the fleet will have a multiplicative impact on the results.

Standardization

Having all vehicles equipped similarly will make it easier for your technicians and training department, and also level the playing field for driver performance and driver pay bonuses.

Staff Workload

Many fleets are in a situation where their technicians are at full capacity or near that point. Taking on additional work to retrofit a new feature interrupts critical day-to-day operations. Post production line installs or on-site upfit specialists can alleviate these challenges.

Challenges

Warranty Coverage

Depending on who and how an item is installed, it may not have warranty coverage and in the absolute worst case, an improper installation could invalidate the warranty coverage for other parts of the vehicle.

Service & Parts Support

Don’t expect the OEM and dealerships to support something that they don’t yet have in production. Be ready with alternative plans to support your customized features on the road.

Introduction & Rationale

Although most OEMs have extensive product offerings, there are so many different technical solutions it isn’t practical for them to offer all features in combination with all other features. If your preferred combination is one that isn’t offered, isn’t yet validated for factory installation, or simply isn’t high volume yet, there are alternative ways to get a component, part or device installed.

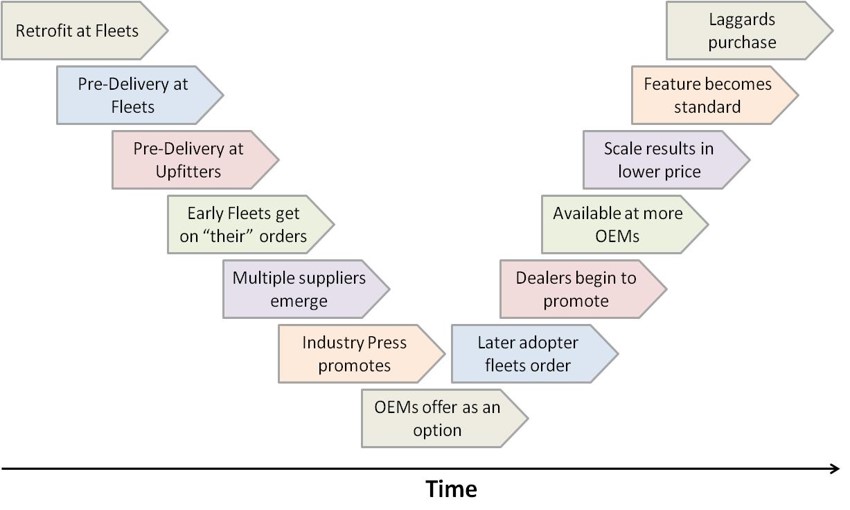

NACFE’s Collaboration Report ICCT Barriers to Adoption found that “lack of access to technologies” was one of the common barriers to the adoption of fuel efficiency technology. The barriers report illustration below shows how new features commonly work their way into the commercial vehicle marketplace in North America. Upfits and retrofits are additional avenues to gain access to features a fleet desires.

Available Systems

Many production assembly plants have nearby facilities that can accommodate features that are not available on the main production line. These facilities go by many different names with some being owned by the OEM themselves, while others are owned by independent sources.

There are also companies that specialize in making upfits in the field. This takes the burden off the fleet’s own shop staff and allows them to continue performing their existing assignments without being disrupted by retrofitting new features to older vehicles. These outside organizations are likely to have more experience with upfits than a fleet and therefore would be faster and more efficient at completing a quality installation.

Weigh & Toll Station Bypass

Using either an RFID transponder or an app, qualified fleets can bypass weigh station and ports of entry facilities. Bypass is based on compliance with federal and state safety requirements along with adherence to credentialing requirements. Toll bypass systems are also available to use in many states that have toll roads.

Benefits

Fuel Savings

A half-gallon of fuel per bypass given the elimination of deceleration, idling and accelerating back up to highway speeds. This also reduced exhaust emissions.

Reduced Inspections

If the vehicle is not stopped in front of people that might notice something to inspect, the likelihood of an inspection and its related costs are reduced.

Time Savings

It is estimated that the average weigh station stop takes between three and five minutes.

Safety

Staying with the normal flow of traffic helps the driver avoid slow moving vehicles that may cause issues and also eliminate the need to accelerate and merge back into traffic.

Cost Savings

Time, equipment wear, fuel and inspections all add to the fleets cost.

Driver Pay

For drivers getting paid by the mile, the time lost to toll and weigh stations creates lost miles and therefore lost pay for the day.

Challenges

Data Inaccuracies

May prevent a qualified fleet from bypassing.

Inability to Connect to Bypass Service Provider

Safety Ratings

If you have more inspections, it can improve your safety ratings. Bypassing weigh stations can minimize the number of inspections. Better safety ratings can increase your rates.

Introduction & Rationale

When a truck equipped with a transponder or bypass app approaches a weigh station bypass it is electronically screened based on criteria including ISS score and IFTA date is reviewed to determine if the truck needs to pull in for an inspection.

The driver will receive a green light if he or she can bypass and a read light if they have to pull in to the weight station. When a truck has to pull into the weigh station the fleet or owner-operator incurs a time, fuel, emissions and cost penalty.

According to The Federal Motor Carrier Safety Administration there is an $8.68 savings per bypass. Toll transponders communicate with automated tolling stations to eliminate the need for a physical transaction at the toll station.

Available Systems

- Transponder

- App for smartphone, tablet or telematics device

Sustainability

Many companies have corporate responsibilities to report on their sustainability metrics and actions. Some shippers require sustainability information from the fleets that they hire to transport freight. We all share one planet, and owe it to each other as well as future generations to do as little damage as possible. NACFE can help you find steps forward for your sustainability efforts.

Introduction & Rationale

The partnership that NACFE enjoys with both the Rocky Mountain Institute and Carbon War Room provides substantial resources, expertise and insights into sustainability. It is a pleasure to be able to provide the assets of these three organizations to provide logistics leaders with support to help them succeed in their efforts to be more “green.”

Fuel Economy & Other Benefits

Although NACFE’s primary focus is to cut the fuel costs and raise productivity in freight transportation, that focus has the additional benefit of reducing use of fossil fuels, minimizing the emissions from trucks and providing additional efficiencies and ranges to all alternative fuels.

Shippers, logistics suppliers and fleets must work together to improve energy efficiency in the transportation system that supports all human needs. Maximizing the ton-miles-per gallon (or gallon equivalent) of fuel regardless of the mode of transportation is beneficial to both the businesses involved as well as the customers and the planet as a whole.

Common Fleet Strategies

Some fleets take large scale steps to change operations with alternative fuels and improve best practices. Other fleets experiment strategically and publicly to show they are investigating new technologies that can be beneficial if the return on investment proves to be positive.

What People Are Saying

Pepsi announced on October 17, 2016 that it has a 2025 Sustainability Agenda. A key portion of this work challenges the organization to “Reduce absolute greenhouse gas emissions across the company’s value chain by at least 20% by 2030, with a focus on collaborating with suppliers, business partners and customers to reduce emissions related to agriculture, packaging and transportation.”

From the UPS Sustainability website in the Fuels and Fleet section: “UPS has a history of more than 10 years of testing and deploying a variety of vehicle types, matched to the terrain and delivery conditions at each location. This approach helps UPS continuously integrate new technologies and operational efficiencies in our large, global delivery fleet. While monitoring each vehicle’s performance, we work with manufacturers, government agencies and non-profit organizations to advance new technologies. Because the more we discover together, the more sustainable we become and the more we help others move forward, too.”

Available Systems

NACFE provides benchmarking spreadsheets as a portion of the Annual Fleet Fuel Study to allow rapid and simple comparisons to industry leading fleets. Our confidence reports are published to provide fleets unbiased reviews of technical solutions including the benefits as well as the consequences. Our workshops provide an open forum for the discussion of best practices.

We are frequent speakers at the “green events” in the industry such as ACT Expo (Long Beach CA), Green Truck Summit (Indy), Green Fleets Midwest Forum (Columbus OH), and DOE Clean Cities events. If you would like our help in finding the right speakers, suppliers, audience and event to meet your interests, please ask us.