Aerodynamic Devices Improve Trailer Airflow

Adding aerodynamic devices such as nose cones, skirts, under body devices, tails, etc. to the generally boxy trailers can improve fuel efficiency.

The higher the speed the more effective these devices become. An obstacle to their adoption is that most fleets have multiple trailers for each tractor limiting the miles driven per year and increasing the payback time.

There is significant data showing fuel savings for the various trailer aerodynamic devices. The priority for device adoption by fleets is skirts, tails, front, and then other devices. Devices have matured and will continue to improve. Skirts have become lighter, less expensive, and more robust improving their payback. Other devices are maturing but need continued development to improve their total cost of ownership.

There are some unique challenges with trailer aerodynamics. These include the trailer-to-tractor ratio, the fact that the purchaser of the aerodynamic device is not the one buying fuel, and the fact that some devices need driver intervention.

Trailer Aerodynamics

What Fleets Are Saying

The overall perception of the savings offered by trailer aerodynamics is positive. “They are really effective devices now,” one fleet owner said.

Fleets stated that aerodynamic device construction, design, and materials have all vastly improved in the past five to seven years. They have become lighter and more robust.

Some fleets feel that drivers have become more accustomed to having aerodynamic devices on trailers and when combined with fuel economy incentive programs, actually appreciate having them.

Fleets were uniform in stating that the devices should “require no driver intervention.” One fleet owner said, “Any statement that starts with ‘All the driver has to do is…’ should be questioned.”

Fleets have been investing in trailer skirts as their first choice for aerodynamic improvements. However, now having done that they are looking at the next steps and are debating the merits of tails versus other options.

What People Are Saying

Data shows that trailer aerodynamic devices help fleets save fuel. The priority for device adoption is side skirts, rear devices and then gap.

– Rob Ulsh, vice president, dealer and international sales, Great Dane Trailers

Decision-Making Tools

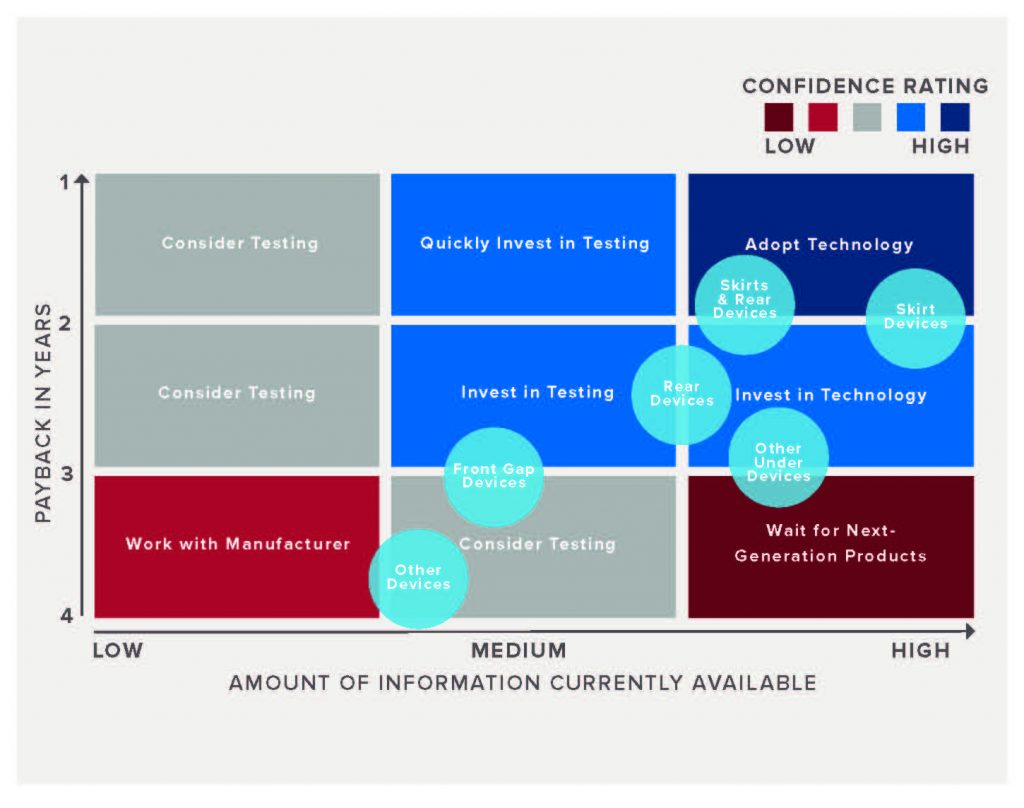

NACFE has developed several tools to help fleets make their decision about trailer aerodynamic devices. The Confidence Matrix, informs fleets of NACFE’s confidence in the technology being studied vs. the payback the fleet should expect to receive from the technology.

Conclusions

- Trailer aerodynamic devices save fuel. There is significant data showing fuel savings for the various technologies. The priority for device adoption by fleets is side, underbody and gap and then other devices. The EPA SmartWay program has made noteworthy progress since its inception in 2004, providing the industry with a structure for cataloging and ranking trailer aerodynamic devices. It should be considered a foundation for further improvement in performance evaluation.

- Devices have matured and will continue to improve. Skirts have become lighter, less expensive and more robust improving their payback. Other devices are maturing but need continued development to improve their total cost of ownership. There is a widespread recognition of the further improvements and efficiency gains that stand to be achieved in trailer aerodynamics.

- Unique challenges exist. These include trailer-to-tractor ratio which limit the miles per trailer, some cases of the trailer aerodynamics purchaser not buying the fuel and lastly, devices should be driver passive: no driver interaction is required to deploy or stow. There are solutions to these challenges.

- Performance for each fleet is difficult to determine. Performance of any device is subject to many variables and each operator will likely have their own experiences. But the standardized test methods are directionally useful in evaluating different devices and combinations of devices. A range of products are now readily available that offer proven savings. As these products have matured, so has the industry’s understanding of the need for improvements in the way fuel efficiency performance is measured and allocated. Advances in test and analysis continue to be made, but the tools available today tend to report performance judged under controlled, focused, operating conditions rather than representing the full range of operations possible in industry. Although most fleets can measure tractor efficiency very closely, they do not have the tools to monitor the trailer efficiency at all.

- Regulations will drive greater adoption. GHG Phase II and CARB rules will drive much greater adoption of trailer aero devices in the near future, taking them from being add-on options to being standard equipment. The Greenhouse Gas Phase II emissions rules are likely to significantly influence trailer aerodynamic technology adoption. The rules have been released but await litigation proceedings before they can be implemented at this time. California’s existing CARB rules, which are linked to EPA SmartWay designated technologies, are already influencing some investment decisions. However, the primary motivation for aerodynamic technology investment remains a business one, with fleets demanding a two year or less payback for technologies.

- Aerodynamic devices must work without driver intervention. History has shown that devices that need driver intervention — such as first generation trailer tails — are not effective solutions as drivers do not deploy them 100% of the time. Second generation rear devices are addressing some of the challenges of the earlier versions of those devices. Future aerodynamic devices must work without needing driver involvement in their operation.

Narrow Mud Flaps

A variety of mud flap alternatives have been on the market for many years offering improved aerodynamic performance and fuel savings. The consensus is that these devices should be beneficial but the amount of fuel saved is hard to determine in individual tests.

One critical aspect of mud flap aerodynamics is specifying the correct width of mud flap for the tires. There are differences between wide-base singles and duals so that one size mud flap does not fit all. A mud flap that is too exposed to the airflow will increase aerodynamic drag and downstream issues.

To learn more, download the Trailer Aerodynamics Confidence Report.

Trailer Fairings

Trailer fairings, frequently referred to as trailer skirts, are the most popular devices for addressing aerodynamic drag on trailers. They prevent wind from ducking in under the trailer and running into the trailer bogie. Fleets and drivers see fewer challenges in operational environments with skirts, as they do not interfere with moving freight in and out of dry van trailers.

Skirts are most effective when they extend from the landing gear to the front face of the front trailer axle and are as low to the ground as possible. Depending on the terrain covered by a particular duty cycle, the skirt may need to be shorter.

The majority of skirts on the market today are flat sheet materials—composite, metallic, or both—bracketed to the underside of the floor structure of the trailer. Formed or molded panels are also available. Various manufacturers include a rubber flexible strip at the bottom of the skirts to help close the gap between the ground and the bottom edge of the skirt. Skirt reliability, durability, and cost have improved over the last five to seven years.

To learn more, download the Trailer Aerodynamics Confidence Report.

Trailer Gap Devices

Tractor-to-trailer gap management devices, commonly called nose cones, are mounted to the front of the trailer, generally near the top, to limit the air gap between the tractor and the trailer. These devices are ranked third in adoption priority. They are best suited for use with day cabs, mid-roof sleepers, and older styled conventional tractors.

Another type of trailer gap device uses the natural tendency for air to swirl in the tractor/trailer gap. They are designed to help maintain these vortices.

To learn more, download the Trailer Aerodynamics Confidence Report.

Part Removal / Relocation – Trailer

Parts such as lights, spare tire racks, and license plates in the air stream can increase drag. Removing or relocating these parts can help reduce drag and improve fuel economy.

Although each part may have a minor effect on drag and fuel economy, when combined these parts can add up to reduced fuel efficiency by as much as a few percent. Each 1% in fuel efficiency can be up to $700 in annual fuel savings, decreasing the value of these add-on parts and making them good candidates for removal.

To learn more, download the Trailer Aerodynamics Confidence Report.

Vented Mud Flaps – Trailer

A variety of mud flap alternatives have been on the market for many years offering improved aerodynamic performance and fuel savings. The consensus is that these devices should be beneficial but the amount of fuel saved is hard to determine in individual tests.

Vented mud flaps are designed with holes or other means of allowing air to flow through while maintaining the function of lowering water spray and deflecting other objects. Many different designs are commercially available and adoption is growing significantly.

To learn more, download the Trailer Aerodynamics Confidence Report.

Wheel Covers – Trailer

The aerodynamics associated with rotating tires and wheels are complicated by many factors. Wheel covers, which are inserted into the wheel of all tires, streamline the airflow around tires. They provide a net benefit to the fuel economy of the vehicle, but the improvement is small.

The cost, weight, and installation time of wheel covers is relatively small compared to other products. One set of four covers for a trailer complete with mounting bracketry may add 20 to 50 pounds to the trailer.

Multiple wheel cover designs are available. The primary design challenge has been making it possible to remove the wheel covers easily so that the wheels are accessible for inspection, maintenance, and repair.

To learn more, download the Trailer Aerodynamics Confidence Report.

Trailer Underbody Devices

Air flowing under the trailer body decreases fuel economy. However, aerodynamic drag under the trailer is complicated especially when ambient winds are not aligned with the tractor and trailer.

Bogie fairings are one type of underbody device. The benefit of the bogie fairing type of system is that it provides greater clearance and access under the trailer than with full skirts.

Other new products are reaching the market that offer more clear space under the trailers than full skirts.

Fleets should also know that underbody devices can collect ice and snow in winter conditions, and this can impact aerodynamic performance, as well as adding weight to the vehicle and reducing its freight load potential or resulting in overweight fines at inspection stations.

To learn more, download the Trailer Aerodynamics Confidence Report.

Trailer Rear Devices

Devices that mount at the rear of trailers have generally been called boat tails or trailer wake devices. They modify the air flow as it leaves the trailing edge of the side and top surfaces of the trailer. The goal in all trailer rear devices is to reduce the wake field following the trailer, which can affect air some distance beyond the back of the trailer.

Many concepts have been developed to help get the air to wrap more efficiently around the trailer rear corners, reducing the size of the wake field and thus reducing the drag. First generation trailer tails showed some initial promise, but because of maneuverability and driver issues they did not gain widespread acceptance.

A new generation of rear devices are beginning to come into the market that address some of the deficiencies with the first generation products.

To learn more, download the Trailer Aerodynamics Confidence Report.

Vortex Generators – Trailer

For years vortex generators where only frequently seen on owner-operator trucks. Higher fuel prices have pushed several major fleets into trying these devices. Some drivers and fleets have used vortex generators on the back edge of the trailer create what they feel is less turbulence behind the trailer.

There are several suppliers of these systems. Some are installed individually while others come in longer strips to allow several to be installed simultaneously.