Big Efficiency Gains Are Seen with Tractor Aerodynamic Devices

Aerodynamic improvement of commercial tractors has been a primary contributor to significant reductions in the fleet operating costs and reductions in harmful emissions by improving the efficiency of the use of energy to move vehicles down the road.

The per-vehicle fuel economy benefit of optimizing the aerodynamics of a tractor can be high. OEMs offer a range of tractor “models,” reflecting broad design elements that are prioritized by each of a certain segment of the trucking industry.

The importance of tractor aerodynamics is well recognized, and is a major consideration of OEMs in designing their base models and they are constantly working to improve the performance of their tractors. Each base model is aerodynamically optimized by the OEM, which will view the entire tractor as a unified system interacting with the air flows.

In addition, there are other areas of the tractor where a fleet may choose to invest in additional aerodynamic devices to further optimize their tractor. This includes things like cab extenders, roof extenders, tractor-trailer gap devices, mirrors and cameras, sunshades, headlamps, bumpers, chassis fairings, drive wheel fairings, fifth wheel location and height, wheel covers and vented mud flaps.

Tractor Aerodynamics

Adding items like tractor-trailer gap devices, chassis fairings, drive wheel fairings and wheel covers, etc., to today’s already aerodynamic tractors, allows fleets to further improve fuel efficiency.

– Laura Ricart, Chief Engineer, Vehicle Performance Integration and Aerodynamics, Navistar

Benefits

Fuel Savings

Due to lower drag

1% to 10% depending on the devices chosen

Improves Stability and Rollover

Trailer aerodynamic devices add surface area to the trailers and modify the trailer air flows. These can slightly improve rollover physics in severe crosswind conditions.

Reduces Splash and Spray

Aerodynamic device equipped trailers reduce drag by improving air flow around the vehicle, which also helps to reduce splash and spray.

Reduces Driver Fatigue

Anecdotal feedback from drivers suggests that trailers equipped with aerodynamic devices are generally less taxing and maintain their lane with less frequent steering correction by the driver.

Challenges

Adds Weight

As trailer aerodynamic devices add weight the critical trade-off between aerodynamic performance improvement and increasing tare weight will depend on the weight-sensitivity of the fleet.

Difficulty Getting Accurate Comparisons Between Devices

The different methods used to test and analyze aerodynamic devices can make it difficult to do accurate comparisons.

Variance Among Aerodynamic Manufacturer Information

Information published by the device manufacturers varies greatly in content, format, and detail.

The Need to Optimize Tractor/Trailer Ratios

The tractor-trailer ratio will indicate the trailers actual annual mileage and the return on investment from the adoption of trailer aerodynamics.

Questions About Durability and Reliability

There are no standards for structural integrity of aerodynamic devices. To survive normal daily operations and should be subject to regular driver inspection and other audits.

May Increase Tire Operating Pressure

Aerodynamic devices can modify the air flow over the brakes and tires resulting in slightly higher operating temperatures.

Common Fleet Strategies

- Each area of the trailer represents an opportunity to reduce aerodynamic drag.

- Both industry and government aerodynamicists have shown that the maximum aerodynamic improvement comes from a combination of sealing the tractor/trailer gap, sealing the trailer underbody, and adding a boat tail.

- As each device is added, the performance of other devices will be impacted. The airflow over each device changes the operating conditions for the other devices. The performance of a combination of devices will not simply be the additive total of each device operating alone. However the greatest aerodynamic drag reduction comes from using devices in three main areas: gap, underbody, and rear. Addressing the aerodynamics of all three points of drag should give the greatest fuel savings for the vast majority of fleets.

What Fleets Are Saying

The overall perception of the savings offered by trailer aerodynamics is positive. “They are really effective devices now,” one fleet owner said.

Fleets stated that aerodynamic device construction, design, and materials have all vastly improved in the past five to seven years. They have become lighter and more robust.

Some fleets feel that drivers have become more accustomed to having aerodynamic devices on trailers and when combined with fuel economy incentive programs, actually appreciate having them.

Fleets were uniform in stating that the devices should “require no driver intervention.” One fleet owner said, “Any statement that starts with ‘All the driver has to do is…’ should be questioned.”

Fleets have been investing in trailer skirts as their first choice for aerodynamic improvements. However, now having done that they are looking at the next steps and are debating the merits of tails versus other options.

We continue to update our fleet with more fuel efficient post-2014 U.S. Environmental Protection Agency emission compliant engines, install aerodynamic devices on our tractors, and equip our trailers with trailer blades, which all lead to meaningful improvement in fuel efficiency.

— Knight Transportation

Appearance and detail of our equipment means a lot to our drivers. Drive wheel fairings don’t just save us money, but our drivers like them too.

— Brad Pinchuk, Hirschbach

Sleeper tractor aerodynamics have been finely tuned by all OEMs. Eliminating various features can add 10% to a fleet’s fuel expense.

– Chief Engineer at a Major Truck Builder

Desicion-Making Tools

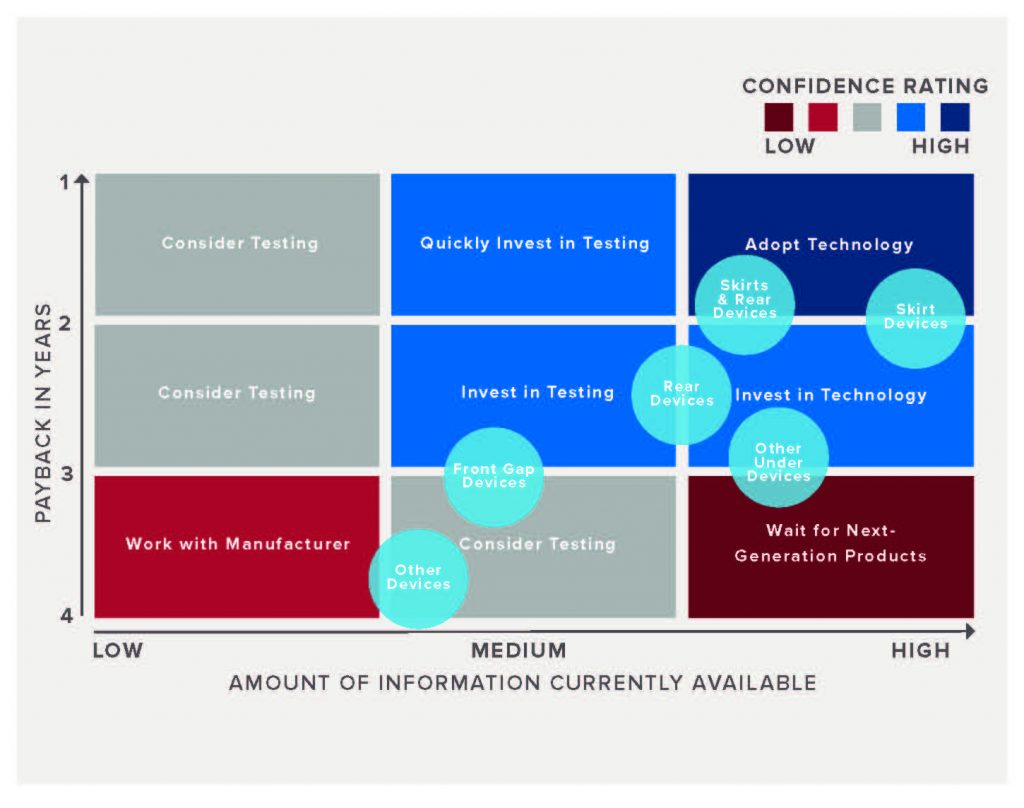

NACFE has developed tools to help fleets make their decision about trailer aerodynamic devices. The Confidence Matrix, informs fleets of NACFE’s confidence in the technology being studied vs. the payback the fleet should expect to receive from the technology. An appendix of SmartWay verified trailer aerodynamic devices can be found at the end of the full Confidence Report.

Conclusions

- Trailer aerodynamic devices save fuel. There is significant data showing fuel savings for the various technologies. The priority for device adoption by fleets is side, underbody and gap and then other devices. The EPA SmartWay program has made noteworthy progress since its inception in 2004, providing the industry with a structure for cataloging and ranking trailer aerodynamic devices. It should be considered a foundation for further improvement in performance evaluation.

- Devices have matured and will continue to improve. Skirts have become lighter, less expensive and more robust improving their payback. Other devices are maturing but need continued development to improve their total cost of ownership. There is a widespread recognition of the further improvements and efficiency gains that stand to be achieved in trailer aerodynamics.

- Unique challenges exist. These include trailer-to-tractor ratio which limit the miles per trailer, some cases of the trailer aerodynamics purchaser not buying the fuel and lastly, devices should be driver passive: no driver interaction is required to deploy or stow. There are solutions to these challenges.

- Performance for each fleet is difficult to determine. Performance of any device is subject to many variables and each operator will likely have their own experiences. But the standardized test methods are directionally useful in evaluating different devices and combinations of devices. A range of products are now readily available that offer proven savings. As these products have matured, so has the industry’s understanding of the need for improvements in the way fuel efficiency performance is measured and allocated. Advances in test and analysis continue to be made, but the tools available today tend to report performance judged under controlled, focused, operating conditions rather than representing the full range of operations possible in industry. Although most fleets can measure tractor efficiency very closely, they do not have the tools to monitor the trailer efficiency at all.

- Regulations will drive greater adoption. GHG Phase II and CARB rules will drive much greater adoption of trailer aero devices in the near future, taking them from being add-on options to being standard equipment. The Greenhouse Gas Phase II emissions rules are likely to significantly influence trailer aerodynamic technology adoption. The rules have been released but await litigation proceedings before they can be implemented at this time. California’s existing CARB rules, which are linked to EPA SmartWay designated technologies, are already influencing some investment decisions. However, the primary motivation for aerodynamic technology investment remains a business one, with fleets demanding a two year or less payback for technologies.

- Aerodynamic devices must work without driver intervention. History has shown that devices that need driver intervention — such as first generation trailer tails — are not effective solutions as drivers do not deploy them 100% of the time. Second generation rear devices are addressing some of the challenges of the earlier versions of those devices. Future aerodynamic devices must work without needing driver involvement in their operation.

5th Wheel Settings

The fifth wheel works in conjunction with the king pin to connect the tractor to the trailer and determine the gap between the two. Some fleets are limiting the travel of sliding fifth wheels to limit the gap when the trailer is in the most rearward position.

There are a number of options for reducing trailer drive height, which can reduce overall drag through the reduction in the profile of the vehicle. Combinations of tire choices and reduced fifth wheel settings can drop the overall trailer roof height.

The biggest influence on drag is the overall frontal area of the vehicle going through the air. Minimizing the fifth wheel height keeps the trailer lower than it otherwise would be, decreasing drag. This effectively lowers the overall height of the vehicle.

Benefits

Fuel Savings (If Coupled with Higher Capacity and Higher Voltage Electrical System)

Challenges

Not Available for Most Vehicles as of March 2017

Increased Complexity of Electrical System

Higher Electrical System Voltage and Power Output Required

Reliability Issues

Increased Maintenance Costs

To learn more, download the Tractor Aerodynamics Confidence Report.

Aerodynamic Hoods, Fenders & Headlamps

The characteristic shapes of aerodynamic sleeper models generally have rounded leading edges, especially at the crown and grille edges, cab A-pillars, and sleeper roof edges. They also generally have conformal headlamps integrated into fenders, curved outer ends to bumpers, bumper air dams, hoods that slope downward at the front, aerodynamic cab access steps, chassis fairings with ground effects skirting, and sleeper extenders. These features are mandatory for vehicles to be classified by the EPA as SmartWay tractors.

Since the early 2000s, aerodynamic sleepers have become the predominant type of tractors in production. Classic sleepers still exist with long and tall hoods, but sacrifice as much as 30% in fuel savings.

Headlamps on aerodynamic tractors are designed as integral parts of the hood shape. Some the OEMs have contoured the headlamps to conform to the body shape. Other OEM models may offer headlamp alternatives, but the aerodynamic flagship models have been aerodynamically optimized around single shapes.

Benefits

Fuel Savings

Due to lower drag.

Better Visibility

Drivers can see objects directly in front of the vehicle and to the forward right and left sides of the tractor.

Challenges

Engine Cooling

Vehicle cooling systems require air flow over a given amount of radiator surface, so there is always a required amount of the hood that is open for air flow.

To learn more, download the Tractor Aerodynamics Confidence Report.

Tractor Gap Devices

The gap between the tractor and trailer has long been a point of known challenges for optimizing aerodynamics. New solutions are now appearing in the marketplace that are significantly different from past ideas.

Tractor-to-trailer gap closure efforts started with cab extenders, sleeper extenders and most recently added sleeper top extenders to the cab. Devices for the front of the trailer have been around for years. Recently new devices have entered the market to deploy at speed to close the gap and then retract as vehicle speed decreases.

Benefits

Fuel Economy

Early feedback shows that savings could be as high as 4 to 5% depending on your equipment, weather conditions, time spent deployed and other factors.

Reduced Emissions & Wear

Less fuel burned means less engine emissions and less engine wear.

Tractor/Trailer Ratio

With many fleets having 3 or more trailers for every tractor, implementing solutions on the tractor are more advantageous and affordable than adding devices to the trailers.

Vehicle Operation

Handling and steering become easier if there is no wind buffeting of the trailer.

Cab Extender Life

Use of these systems may allow fleet to run shorter extenders and avoid the cost of damaged extenders.

Challenges

Weight

These systems add at least a minor amount of weight to the vehicle.

Cost

The system adds electronic controls in addition to the physical components.

Damage Potential

It isn’t hard to find a tractor with damaged cab extenders so protecting these devices from damage is a challenge unless designed to stay out of the trailer swing path.

To learn more, download the Tractor Aerodynamics Confidence Report.

Aerodynamic Bumpers

Aerodynamic bumpers are contoured to better match the shape of the underside of the hood and fender area. They curve under to replace flatter bumpers, which act as snowplows to the air.

Where OEMs diverge on aerodynamic bumper design is with air dams under the bumpers. OEMs have investigated a variety of options to optimize this area. The air dam tends to decrease the front clearance to the ground. This reduction in ground clearance causes the aerodynamic stagnation point to move. The location of the stagnation point affects the share of air that is routed under the vehicle, to the sides of the vehicle, into the grille, or over the top of the vehicle.

Benefits

Fuel Savings

Due to lower drag.

Challenges

Initial Cost

Historically, add-on aerodynamic features for tractors incurred a higher initial cost. This is still the case for some of the optional devices.

Maintenance (Damage and Repair)

Some aerodynamic devices cover up other vehicle features that need periodic maintenance; devices can also be damaged during use.

Accessibility of Engine Compartment and Front of Tires

Some aero devices make it more be more difficult to reach engine.

To learn more, download the Tractor Aerodynamics Confidence Report.

Aerodynamic Mirrors & Cameras

OEMs’ flagship aerodynamic models have optimized the cab mirror systems. Aerodynamic mirrors come as an integrated set with an aerodynamic cover that lowers drag.

With well-designed mirrors, aerodynamic drag can be reduced by 2% to 3%. Considerable OEM and supplier tradeoff studies and analysis have optimized production mirror head shapes and mounting systems.

For many years, federal regulations required two rear-vision mirrors, one on each side of the truck. In 2018, Stoneridge asked for and received an exemption from FMCSA to allow trucks to operate with its MirrorEye, a camera monitor system that replaces mirrors on trucks.

Benefits

Fuel Savings (If Coupled with Higher Capacity and Higher Voltage Electrical System)

Challenges

Not Available for Most Vehicles as of March 2017

Increased Complexity of Electrical System

Higher Electrical System Voltage and Power Output Required

Reliability Issues

Increased Maintenance Costs

To learn more, download the Tractor Aerodynamics Confidence Report.

Roof Fairings

Roof fairings will improve fuel efficiency, and the more aerodynamically shaped the roof air fairing, the better the fuel economy.

For 53′ dry vans and refrigerated trailers, full height roof fairings create a smooth transition from the windshield to the full height of the trailer. These fairings may simply be the top of a full-height sleeper cab or an additional part above a low, mid, or high cab.

For day cabs, a roof fairing is often an additional part that can be mounted to the low-roof cab. In some cases, an adjustable roof fairing can be installed and lowered to limit drag when the tractor is not pulling a trailer.

For tanker or flat bed trailers, tractors and their cab height should be specified to match the trailer as best as possible. Using a full-height cab that generally matches a 53’ van trailer will create higher drag than needed and thereby increase fuel expense up to 10%.

Benefits

Fuel Savings

Due to lower drag.

Sharper, Integrated Appearance

A roof fairing and cab designed as one integrated system improves vehicle appearance.

Challenges

Initial Cost

Historically, add-on aerodynamic features for tractors incurred a higher initial cost. This is still the case for some of the optional devices.

Not Suited to All Applications

Full-height roof air fairing decreases fuel economy in bobtail, or in trucks hauling flat or tanker trailers.

To learn more, download the Tractor Aerodynamics Confidence Report.

Part Removal / Relocation – Tractor

Removing the fender or hood-mounted mirrors, grille guards, bug deflectors, sunshades, quarter fenders, and other features in the main air flow can lower resistance while the truck is in motion.

Each individual part can have a minor effect on drag and fuel economy; combined, they can add up to reduced fuel efficiency by as much as a few percent. Each 1% in fuel efficiency can be up to $700 in annual fuel savings, decreasing the value of these add-on parts and making them good candidates for removal.

For more information on the effectiveness of removing parts, we recommend contacting your tractor builder.

Benefits

Fuel Savings (If Coupled with Higher Capacity and Higher Voltage Electrical System)

Challenges

Not Available for Most Vehicles as of March 2017

Increased Complexity of Electrical System

Higher Electrical System Voltage and Power Output Required

Reliability Issues

Increased Maintenance Costs

To learn more, download the Tractor Aerodynamics Confidence Report.

Chassis Fairings

The purpose of a chassis fairing, sometimes called a chassis or fuel tank skirt, is to provide a clean aerodynamic surface and eliminate the steps, air, fuel and diesel fluid tanks, battery boxes, etc. that increase the drag of an exposed chassis. They also are designed to kick air slightly outboard of the tractor drive wheels, preventing the air from directly impacting the face of the tire tread.

Chassis fairings run from the cab steps to the end of the sleeper or with extensions to the first drive wheel. Sleeper chassis fairings generally are required for SmartWay designated tractors.

Benefits

Fuel Savings (If Coupled with Higher Capacity and Higher Voltage Electrical System)

Challenges

Not Available for Most Vehicles as of March 2017

Increased Complexity of Electrical System

Higher Electrical System Voltage and Power Output Required

Reliability Issues

Increased Maintenance Costs

To learn more, download the Tractor Aerodynamics Confidence Report.

Drive Wheel Fairings

The aerodynamics associated with rotating tires and wheels are complicated by many factors. Drive wheel fairings mounted between and behind the drive wheels of the tractor streamline the airflow around the rotating tires and direct airflow as it leaves the tractor. They provide a net benefit to the fuel economy of the vehicle, and are often used in combination with wheel covers on the tractor for a higher net benefit. Fuel savings for these devices are estimated to be about 2%.

It is also believed that these devices improve appearance and help reduce water spray.

Benefits

Fuel Savings (If Coupled with Higher Capacity and Higher Voltage Electrical System)

Challenges

Not Available for Most Vehicles as of March 2017

Increased Complexity of Electrical System

Higher Electrical System Voltage and Power Output Required

Reliability Issues

Increased Maintenance Costs

To learn more, download the Tractor Aerodynamics Confidence Report.

Cab & Roof Extenders

These devices close the gap between the tractor and the trailer by extending the vehicle side surface into the gap while ideally not interfering with trailer swing and dip motions.

The purpose of cab and roof extenders is to restrict the airflow from entering into the trailer gap by shortening the effective tractor/trailer gap width to route air over and around the gap to the trailer.

Without extenders, air leaving the rear edge of the tractor would hit the front edge and face of the trailer causing an increase in drag.

Benefits

Fuel Savings (If Coupled with Higher Capacity and Higher Voltage Electrical System)

Challenges

Not Available for Most Vehicles as of March 2017

Increased Complexity of Electrical System

Higher Electrical System Voltage and Power Output Required

Reliability Issues

Increased Maintenance Costs

To learn more, download the Tractor Aerodynamics Confidence Report.

Wheel Covers – Tractor

Wheel covers are inserted into the wheel of all tires to streamline the airflow around the tires and can be used on all six wheel ends of a tandem axle tractor.

A variety of manufacturers produce aerodynamic wheel covers, and small benefits can be achieved by using them as part of an overall fuel efficiency strategy. Wheel covers are made of a variety of materials including aluminum, polycarbonate, and even cloth.

The primary design challenge has been making it possible to easily remove the wheel covers so that the wheels are accessible, while maintaining strong attachment to the vehicle over the road.

Benefits

Fuel Savings (If Coupled with Higher Capacity and Higher Voltage Electrical System)

Challenges

Not Available for Most Vehicles as of March 2017

Increased Complexity of Electrical System

Higher Electrical System Voltage and Power Output Required

Reliability Issues

Increased Maintenance Costs

To learn more, download the Tractor Aerodynamics Confidence Report.

Vented Mud Flaps – Tractor

Vented mud flaps are designed with holes or other means for allowing air to flow through the flaps while maintaining the function of lowering water spray and deflecting objects.

Many different designs are commercially available and adoption is growing significantly.

Benefits

Fuel Savings (If Coupled with Higher Capacity and Higher Voltage Electrical System)

Challenges

Not Available for Most Vehicles as of March 2017

Increased Complexity of Electrical System

Higher Electrical System Voltage and Power Output Required

Reliability Issues

Increased Maintenance Costs

To learn more, download the Tractor Aerodynamics Confidence Report.

Vortex Generators – Tractor

Keeping the air flowing smoothly across the tractor-to-trailer started with cab extenders, sleeper extenders and most recently added sleeper top extenders to the cab. Some drivers and fleets have used vortex generators on the back edge of the cab or extenders to further guide the air flow to the trailer.

There are several suppliers of these systems. Some are installed individually while others come in longer strips to allow several to be installed simultaneously.

Benefits

Fuel Savings (If Coupled with Higher Capacity and Higher Voltage Electrical System)

Challenges

Not Available for Most Vehicles as of March 2017

Increased Complexity of Electrical System

Higher Electrical System Voltage and Power Output Required

Reliability Issues

Increased Maintenance Costs