Consider Trailer Technologies and Practices to Improve Efficiency Efforts

Trailers are playing an increasingly large role in fleets’ fuel efficiency efforts.

There are several technologies and practices that fleets should consider for their trailers.

- The trailer is a prime spot for solar panels to extend battery life and to help manage the electrical load that has been added to modern trailers. Emissions regulations combined with fuel economy features and driver amenities have added 1,000 lbs. to the typical Class 8 truck.

- Lighweighting can significantly reduce tractor weight to offset the increased weight of other components or to allow more payload to be caried increasing the vehicles fright efficiency.

- Lift axles on trailers can help manage light loads, empty back hauls or diminishing load delivery applications.

- The use of double or triple trailers can allow for more payload to be moved per gallon of fuel consumed. A dolly and appropriate electrical and air equipment are required to attach one trailer to another.

- Powered axles provide regenerative braking which can not only save on brake wear, the energy can be captured and used in situations where additional power is beneficial such as vehicle launch or steep/lengthy inclines to decrease fuel consumption.

To learn more, download the Trailer Aerodynamics Confidence Report.

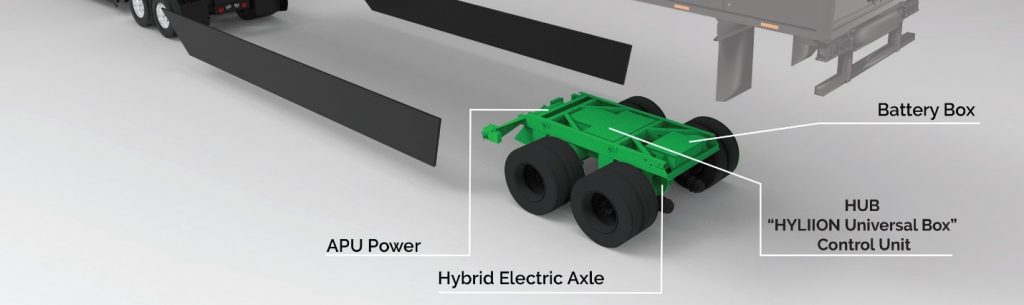

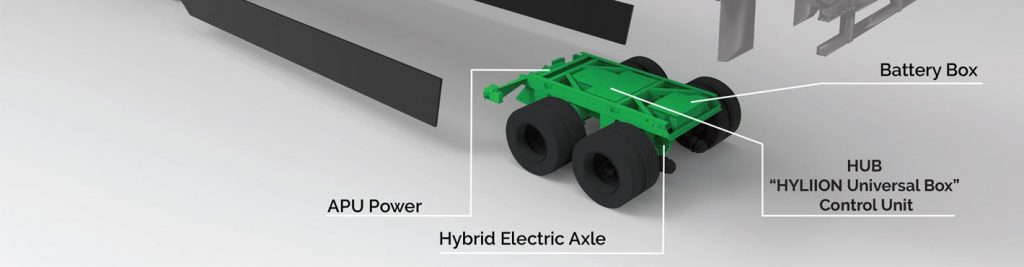

Powered Axle

Regenerative braking can not only save on brake wear, the energy can be captured and used in situations where additional power is beneficial such as vehicle launch or steep/lengthy inclines to decrease fuel consumption

Numerous models of hybrid and battery electric passenger cars already utilize regenerative braking and now this technology is coming to commercial trailers. A drive axle is used for one of the trailer axles in this new strategy. During downhill runs and during braking situations, the axle powers an electric motor-generator which stores the generated electric power in a lithium ion battery pack. When appropriate for power to be applied via this axle the process is reversed.

Benefits

Fuel Economy

Little data is available for this system, but expectations are for a 5 to 15 percentage improvement in fuel economy.

Available Power

The storage battery can supply power to other electrical systems if so designed to power the trailer refrigeration or power any trailer telematics features. With additional lines back to the cab, it may also be possible to provide battery support for HVAC or hotel loads.

Challenges

Weight

The system adds 400 to 500 pounds to the trailer.

Cost

The system adds several expensive components including an automated control system.

To learn more, download the Trailer Aerodynamics Confidence Report.

Double & Triple Trailers

The use of double or triple trailers (often called longer combination vehicles) can allow for more payload to be moved per gallon of fuel consumed.

Given the dramatic improvement in aerodynamic drag and lower rolling resistance of tires, today’s tractors have plenty of power to pull the resulting heavier and longer loads. A dolly and appropriate electrical and air equipment are required to attach one trailer to another.

Double or triple trailers can be dropped at a location and picked up by a different tractor, improving logistics flexibility but requiring more management of the trailers and the dollies required to pull the second trailer. In addition, they cannot be used nationwide, since only some states permit their use.

To learn more, download the Trailer Aerodynamics Confidence Report.

Trailer Lift Axles

For trailers that spend a significant portion of their life with light loads, empty back hauls or diminishing load delivery applications, a lift axle can be utilized for a variety of benefits.

Lift axles have long been part of dump truck specs and have been growing in use on 6×2 chassis configurations. They are also now being seen on dry van trailers as well. Air pressure on the trailer suspension non-lift axle air bags operates the system automatically.

Benefits

Fuel Economy

Eliminate the rolling resistance of one axle’s tires when empty or lightly loaded.

Weight Transfer

The tractor is designed to have weight on the gear set, so lifting the front trailer axle puts more weight on the rear of the tractor. This minimizes tire slip and makes the gear set more efficient.

Reduced Tire Wear

Tire life of the lift axle’s tires is enhanced by reduced use when lifted: both due to normal rolling and due to scrub during turns. The trailer tires remaining on the ground also have better wear since they have an optimized trailer footprint.

Brake Wear

Brake life of the lift axle is enhanced when it is not loaded and the other axle has better wear with the proper tire footprint.

Reduced Toll Costs

If the axle is not touching the ground, some tolling points will not charge for that axle. Kansas, Oklahoma, Florida, and Illinois are just some of the states where this can happen.

Challenges

Toll Challenges

Although booth attendants will be able to see the lifted axle in daylight, don’t expect all of them to believe you in the dark of night. This feature is not that common yet. If using automated tolling, the benefit of a lifted axle may not be possible if the system cannot detect it.

Purchase Cost

Slightly higher than normal, especially since air ride suspensions are more expensive than spring rides.

Axle Flex & Roll Stability

If you plan to run the single axle up to its weight rating, it is worth discussing whether a higher rating is better for your application.

What People Are Saying

We added trailer lift axles for NACFE’s Run On Less demonstration and our experience with them has been very positive with no obvious downsides.

– Joel Morrow, Ploger

To learn more, download the Trailer Aerodynamics Confidence Report.

Solar Panels –Trailer

Interest in solar panels is growing among fleet managers because the batteries are not able to meet the power needs of today’s trucks.

Solar panels designed for the trucking industry are almost all flexible, thin, lightweight, and capable of being affixed to even curved surfaces.

Trailers have traditionally been powered by the seven-way connector between the tractor and the trailer, which powers brakes, running lights, and blinkers. However, as trailers have evolved, a number of other electrical loads have been added to trailers that make the electrical system significantly more complicated. Many of these electrical demands can be supported by solar panels. Possible applications for trailers include support for liftgates, telematics, and refrigeration units.

The extra power available from the solar panel(s) can augment that coming from the engine alternator maintaining the batteries at a higher average state of charge, extending battery life.

A properly sized solar panel can provide additional current and battery charging capacity to help manage refrigeration units, electric liftgates and telematics devices.

Benefits

Location via Telematics

The use of solar panels on the trailer can allow GPS location systems to remain alive nearly indefinitely. This is a significant benefit to fleets for managing trailer locations.

Reefer Monitors

Refrigerated trailers are under increased requirements for temperature monitoring in food logistics. Solar panels can keep the monitor system alive and charged even without the tractor being connected.

Sensor Functionality

Trailer solar panels can provide battery power to implement new features such as trailer door monitoring, brake pads monitors, reefer temperature sensors and more. Some sensors can be wirelessly linked to the telematics system.

Liftgates

Solar systems can charge trailer liftgate batteries to insure the liftgate is always functional regardless of how often the trailer is being charged from the tractor. This can also minimize any idling required to run the liftgate.

Battery Life

Keeping a proper state of charge may extend the life of a trailer’s liftgate or reefer battery system. It may also reduce the roadside support calls to support these systems. Use of solar power may also eliminate using a DC-to-DC voltage converter to boost voltage of the trailer batteries.

Challenges

Trailer Ratio & Portability

Many fleets have 3 or more trailers for every tractor. Equipping all trailers could be costly since these systems are not portable from trailer to trailer.

Sun Exposure

Panels can only augment liftgate electrical systems during daylight hours. But opposed to tractor solar systems, the trailer systems are always on the top of the vehicle so directional issues during daylight hours are minimized.

Cleanliness

Dust, dirt and snow can reduce the solar conversion effectiveness. Check out stories of the Mars rover to see dust in the most extreme environments. The coatings on most panels minimize this issue.

Purchase Cost

Initial system cost and installation.

Variable Results

Latitude directly ties to the angle of the sun and length of solar exposure as well. Cloud levels vary by geographical regions as well.

Residual Value

It is unclear what the residual value for solar systems will be in the future.

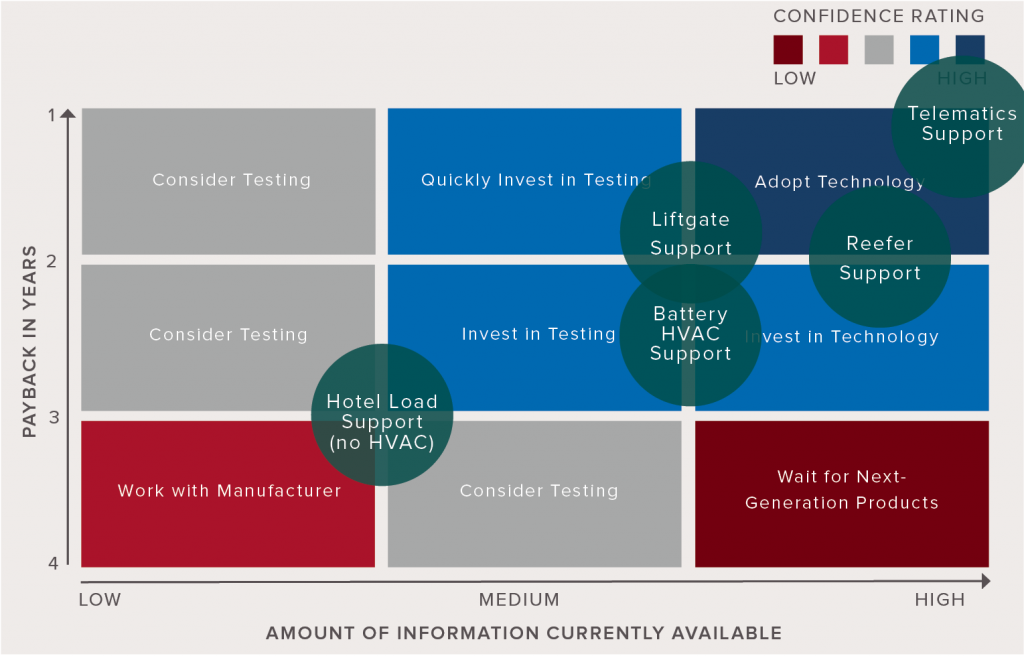

Decision-Making Tools

The study team developed a tool to help fleets in making their decision about solar panels. The confidence matrix is used to inform fleets of the study team’s confidence in the technology being studied vs. the payback a fleet should expect to receive from the technology.

Conclusions

- Solar technology for trucks has progressed to the point where the panels on the market are flexible, thin, easily installed and reliable. Some applications, like supporting the batteries for trailer telematics systems, are an excellent application of the technology and should be strongly considered for future purchases. For other applications of solar technology, the cost versus benefits should be evaluated to see if it makes sense in the specific application.

- Fuel savings are generally a very small part of the overall benefit that comes from a solar panel installation.

- Solar panel installations need to be sized appropriately for their intended application.

- There is limited evidence at this point from fleets that the payback from the investment in solar panels matches that claimed by the solar panel suppliers. Benefits fall in several categories with the biggest benefits being from extending battery life and avoiding emergency roadside assistance for dead batteries.

Future Perspective

The field of solar as applied to trucks is a constantly and rapidly evolving one. The future might lead to improved technologies, cost reductions, more electrification of trucking loads, and extended trade cycles, all of which would make solar systems even more attractive and cost-effective for fleets.