NACFE Shares Its Insights

From time to time there are topics not related to products, components or vehicles that NACFE believes need to be explored more in-depth. These topics do not fit into the Confidence, Guidance or Collaboration Report format for which NACFE is known.

However, using the same research process developed for its other reports, NACFE provides insights into these subjects in the hopes of bringing clarity into what oftentimes is a confusion of information.

SuperTruck 2: Empowering Future Trucking

In 2009, the U.S. Department of Energy (DOE) inspired American truck manufacturers by funding the first SuperTruck project to demonstrate a system of new technologies with the goal of greatly improving freight energy efficiency, reducing vehicle operating costs and improving environmental sustainability. The hugely successful demonstrations led to DOE funding the even more aggressive SuperTruck 2 program beginning in 2016.

The SuperTruck 2 opportunity to harness the creativity of OEMs and suppliers to push the envelope of vehicle design was embraced by five teams lead by:

- Cummins Inc. & Peterbilt

- Daimler Truck North America (DTNA)

- Volvo Trucks

- Navistar

- PACCAR Inc.

Video to Come

From 2016 through 2024, each of these five teams succeeded in innovating complete tractor-trailer systems capable of exceeding freight efficiency performance improvements of more than 100% versus each team’s Model Year 2009 baseline diesel tractors with standard 53’ dry van box trailers. These accomplishments created a watershed of practical engineering and operational information to assist in developing production tractors and trailers to meet the increasingly demanding performance needs of the North American freight industry.

The fundamental basis of these SuperTruck 2 demonstrations is that a systems engineering perspective, encompassing the entire tractor-trailer as a single performing unit, can yield significantly better performance improvements than more piecemeal approaches looking at optimizing individual systems.

SuperTruck 2 teams had essentially two goals. One was to demonstrate a 55% brake thermal efficiency (BTE) engine in an engine test stand. The second was to demonstrate a complete tractor-trailer vehicle system that exceeded a 100% improvement in freight-ton-efficiency (FTE) versus their selected MY2009 baseline vehicle with a gross vehicle weight of 65,000 lbs. in a representative on-highway long-haul duty cycle of their own choosing.

Conclusions

- Fuel Economy Improvement: SuperTruck 1 vehicles demonstrated MPGs in the range of 11 to 13 MPG and FTEs greatly exceeding their target 50% improvement versus their MY2009 baseline. The SuperTruck 2 technologies had a target of exceeding 100% versus those same baselines and MPGs as much as 16 MPG by further optimizing diesel technologies, and incorporating 48V mild hybridization and in one case, full high-voltage hybridization. NACFE estimates the equivalent MPG for the emerging battery electric vehicles is starting at 18.5 MPGe. The performance of the SuperTruck 2 demonstrations shows there are significant efficiency gains remaining for diesel-powered vehicles, but it also highlights the complexity required to achieve those gains. SuperTruck 3 and also the associated hydrogen programs are innovation solutions for battery electric and fuel cell medium- and heavy-duty trucks in development over the next five years, hopefully with prototype vehicles seen in public as early as 2026.

- Innovation Diffusion: Trucks that exist as ideas, what NACFE terms “paper trucks,” are part of the research and development process, but they are easily debated as they largely lack real-world testing. The SuperTruck vehicles are real-world trucks evaluated strenuously by expert teams that have skin in the game with their own money, resources and reputations along with funding from the government. Teams often include participants not typically allowed behind the wall of proprietary development at OEMs including national laboratories and university researchers. Potentially excellent ideas that normally sit on shelves from lack of management engagement or interest can make it into full system development of vehicles. Development perspectives that may be hamstrung with component-level development are set free to bloom by participating in a complete vehicle system perspective where, for example, performance gains in one area are achieved by weight reductions or simplification in completely unrelated areas of the vehicle. SuperTruck projects empower designers to literally think outside the mental boxes they typically must work within under normal organizational product development.

- Universal Ideas: Many tractor-trailer system efficiency gains are universally applicable to all powertrain choices. Reducing the energy required to move freight over a distance means less operational cost. Another way to view that is that less energy required per mile can translate into greater net range for the same amount of energy, and/or greater payload. Improving the tractor-trailer as a system is a key perspective to help emerging zero-emission vehicles to achieve more miles per fill-up. Future trucks will build from technologies demonstrated in SuperTruck 2 to achieve increased range and freight capacity. For example, a 100% improvement in MPG easily demonstrated by SuperTruck 2 teams would make a 300-mile BEV capable of going 600 miles.

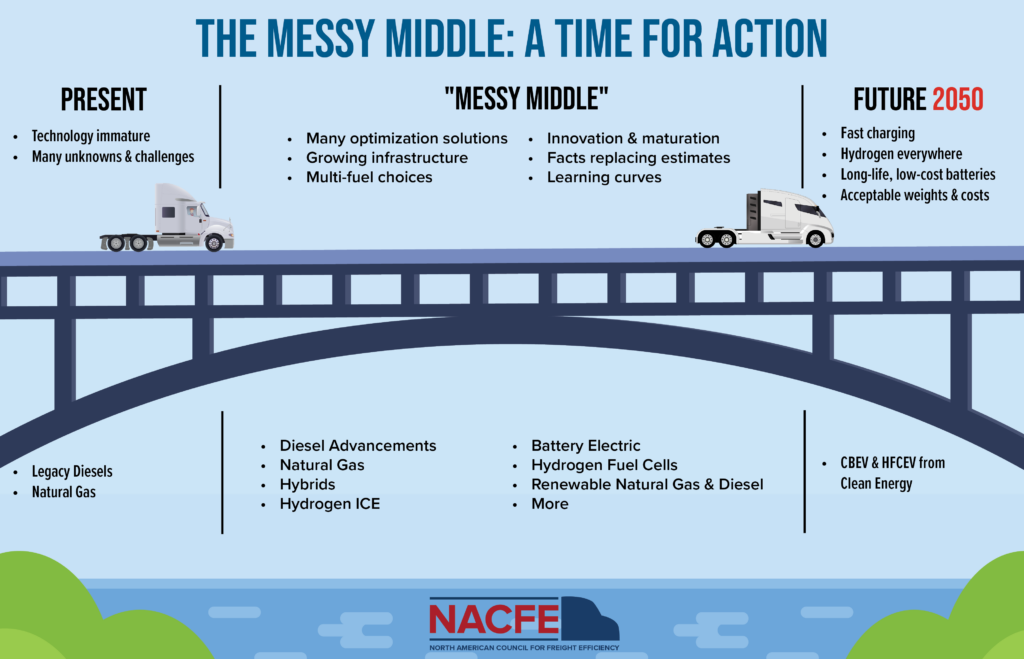

The Messy Middle: A Time For Action

The messy middle is a time between now and when the trucking industry gets to the zero-emission movement of freight. In 2019, the North American Council for Freight Efficiency (NACFE) began using the term and it since caught on and is used by many people involved in the transportation of goods.

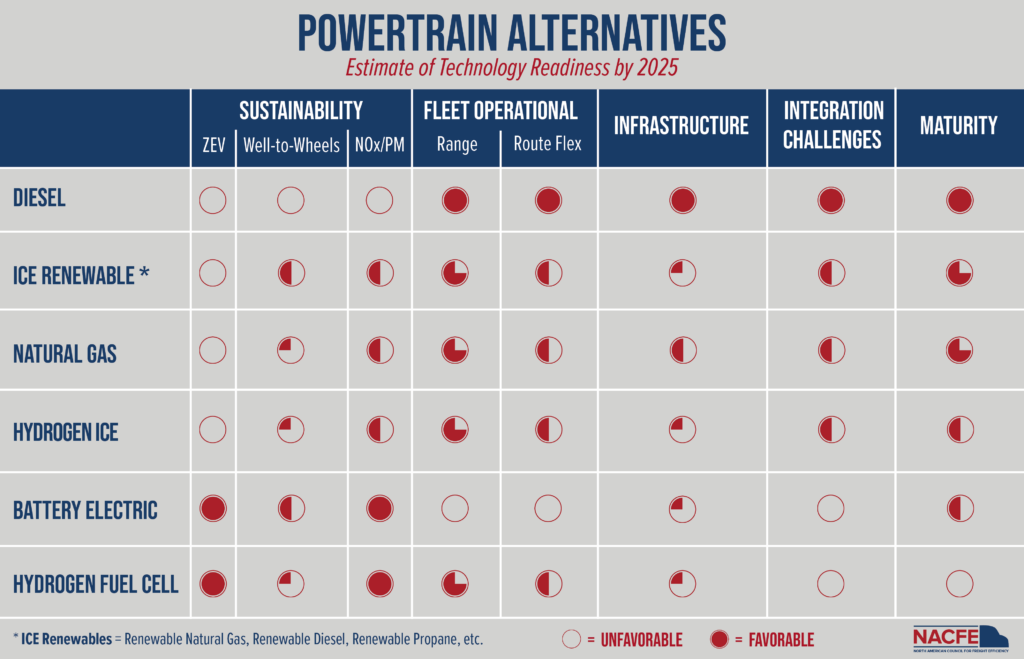

NACFE recently explored the myriad powertrain options — advanced diesel, renewable fuels, natural gas, hydrogen, hybrids, battery electric power and hydrogen fuel cells — available to fleets in the messy middle.

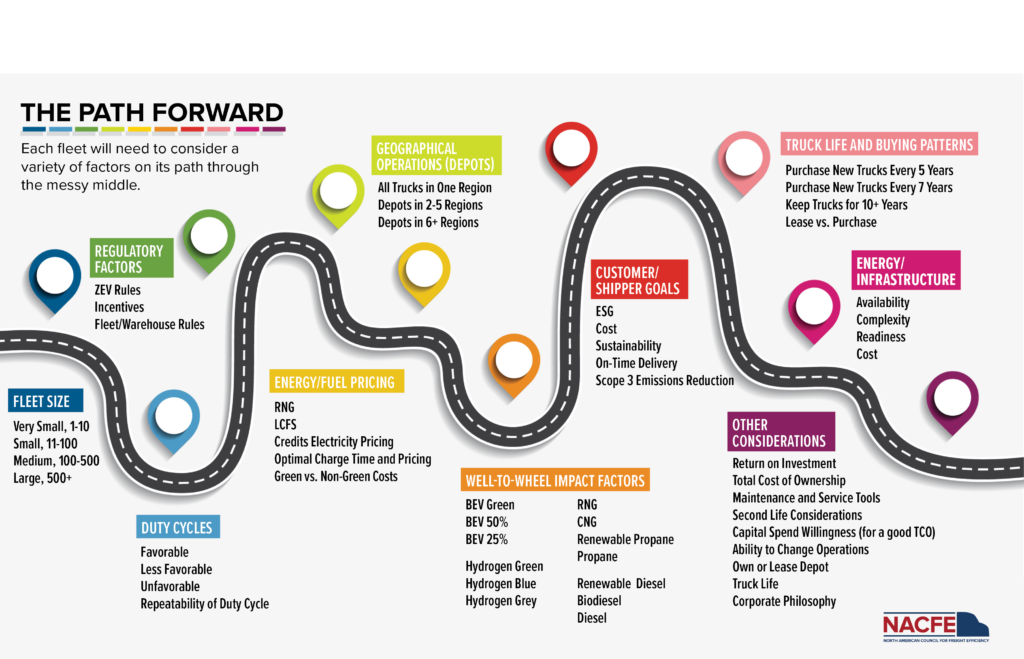

The report contains the analysis of benefits and challenges of each option and lays out the factors fleet managers need to consider when deciding which technology or technologies to deploy in their operations.

While the messy middle can be complicated, NACFE does not view messy as bad, but rather sees it as a time where fleets will have to evaluate many options and look beyond just the truck to the infrastructure needed to support that truck. It is critical that fleets have reliable data on which to base their decisions in order to make proper choices.

Conclusions

The primary conclusion of the report is that it is now time for fleets to act and begin to wade into the messy middle in order to get to a zero-emissions future. Waiting is no longer an option.

Other conclusions include:

- All stakeholders should support fleets in making the right adoption decisions. This includes OEMs, suppliers, utilities, charger manufacturers, regulators, etc.

- Decisions should include a realistic understanding of your pipeline capabilities. Each stakeholder needs to realistically evaluate their strengths and weaknesses and not over promise solutions.

- An even higher level of collaboration is essential. Fleets cannot traverse the messy middle on their own. They need to engage with utilities, governmental agencies, charging equipment manufacturers, OEMs, and others to leverage all the available knowledge.

Decision Making

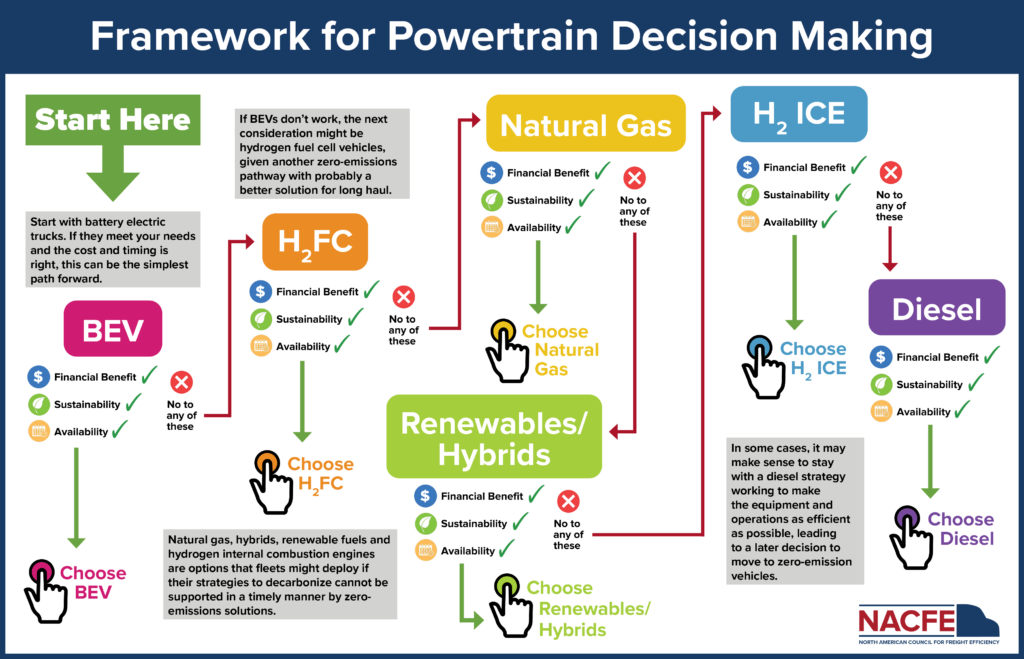

NACFE also developed a best practice for decision making to help fleets evaluate their options.

- Start with battery electric trucks. If they meet your needs and the cost and timing is right, this can be the simplest path forward and a single change for your fleet.

- If BEVs don’t work, the next consideration might be hydrogen fuel cell vehicles, given another zero-emissions pathway with probably a better solution for long haul. (This assumes that the technology matures, and green hydrogen becomes more available.)

- Natural gas, hybrids, renewable fuels and hydrogen internal combustion engines are options in the messy middle that fleets might deploy if their strategies to decarbonize cannot be supported in a timely manner by zero-emissions solutions.

- In some cases, it may make sense to stay with a diesel strategy working to make the equipment and operations as efficient as possible leading to a later decision to move to zero-emission vehicles.

NACFE’s 2020 Collected Works

Throughout the year, Mike Roeth, executive director of the North American Council for Freight Efficiency (NACFE), other NACFE team members, and staff from NACFE’s partner RMI, produce blogs and articles on a variety of freight efficiency-related topics.

These blogs appear in a variety of media outlets and are consumed individually in what we would like to think of as small, savory bites. However, taken together they represent a complete meal or even a week of meals — a quality collection of NACFE thought leadership on the current and future state of freight efficiency.

For the first time, NACFE has gathered its bylined blogs and think pieces into one place — NACFE’s 2020 Collected Works.

The Collected Works is divided into six sections that represent topics on which NACFE consistently commented throughout 2020:

- Autonomous Trucking

- Efficiency Technologies

- Electric Trucks

- Freight Efficiency

- Regional Haul

- Trucking Careers

It will come as no surprise that some topics — like electric trucks and regional haul — generated more commentary than some of the others. But all six topics play into improving freight efficiency now and in the future.

Mike Roeth’s Buckendale Lecture

NACFE’s Executive Director, Mike Roeth, was honored to be named the 2020 SAE L. Ray Buckendale lecturer for the SAE COMVEC event in September 2020. This honor included writing a manuscript entitled, Transformational Technologies Reshaping Transportation – An Industry Perspective.

The Buckendale lecture is an opportunity for SAE to select one individual each year worthy of recognition for significant contributions to the commercial vehicle industry and for advancing understanding of commercial vehicle design, manufacture, operation, and maintenance. It is a career milestone event reflecting on the expertise and contribution of the awardee.

In his lecture, Mike spent time looking back at the recent history of the industry and he looked at many nuances of the trucking industry that are critical in order to bring technologies to market that fleets want to buy. He also shared insights from early fleet pioneers (PepsiCo, UPS and NFI) in electric truck deployment via three case studies.

The lecture can be viewed and downloaded below.

This information can help new commercial vehicle professionals and even us more experienced professionals deal with the transformational changes in technology taking place in the industry today.

NACFE has been fortunate to have three Buckendale winners: Dave Schaller, industry engagement director, in 2006; Rick Mihelic, emerging technologies director, in 2016; and Mike Roeth, executive director, in 2020.

Defining Production

This report provides insights on defining the term production to help demystify it for industry, fleets, regulators, the public, and researchers. A core factor differentiating how the term is used relates to levels of risk acceptance.

Fleets frequently ask truck makers when a truck will be in production. Unfortunately, the term “production” is not strictly defined and can mean different things to different OEMs, customers, regulators, media and the public. There is no one definition for production beyond being a point in time where a new product comes off of a production line and is commercially provided to an end use customer.

The maturity of the product at that point may vary significantly between OEMs. That maturity includes the level of risk the customers assume that the vehicle they are purchasing will be configured for and operate as needed for their specific duty cycles. That risk will be measureable, after-the-fact through on-going maintenance costs, warranty claims, downtime measurements, number of product recalls, number and frequency of software updates (whether over the air or in shop), life of product, etc.

It is relatively easy to create “show” trucks for public events and low volume prototypes for limited track and road testing as a judicious application of money, priority and people can get one to a few built in six weeks to six months. Commercial production trucks, however, to be legally and safely classified as “production,” can take years (four to six years is common).

Conclusions

- Many definitions exist for a statement by truck builders that they are in production causing confusion with stakeholders.

- Product development is an investment in a new product that reduces collective risk over time through testing and decision making.

- There are dramatically differing situations for established versus new OEM entrants, including such items as established development processes, revenue needs, variation of product offerings and risk acceptance levels.

- Fleet expectations for cost of operation, performance, reliability and durability, etc. will not change and in fact be more demanding.

In the end, whatever changes the future reveals in OEMs launching new products, fleets will continue to expect to operate their products with acceptable uptimes, improved safety and low cost of operation. The OEMs that place too great a burden on fleets by introducing immature products will lose out in the long run to more robust ones. Fledgling new technologies risk slower adoption as well if immature products have poor real-world performance due to companies accepting greater risk to achieve near-term cash flows.

Intentional Pairing

The North American Council for Freight Efficiency (NACFE) investigated the factors relevant to intentionally matching a specific tractor model to specific trailer model in logistics systems for the purpose of maximizing fuel economy, minimizing emissions and improving profitability. Many have said, if a specific tractor and trailer can be designed as a system and always operate together additional fuel savings can be attained.

NACFE determined that the vast majority of tractors pulling dry van and refrigerated 53-foot trailers operate in a drop and hook mode, keeping the tractor assets moving as much as feasible rather than waiting for trailers to be loaded or unloaded. Except in some very specific cases, such as in lightweighted tractors and trailers for use in dedicated routes for beverage hauling, intentional pairing of specific tractor and trailers is not a practical consideration for North American goods movement.

In fact, given NACFE’s findings on Regional Haul (link) because of factors such as e-commerce, technology advances and big data, the industry is poised to take advantage of more drop and hook operations decreasing the opportunities for intentionally pairing individual tractors and trailers.

Findings

- Intentional pairing today only occurs in isolated cases such as special purpose hauling where the trailers are customized for specific loads, promotional or event vehicles, and fleets with small numbers of tractors and trailers. And while intentional pairing is feasible, it is not realistic given the realities of today’s trucking industry

- Trailer pools or “drop and hook” is a fixture in North American goods movement and helps with asset utilization and overall goods movement efficiency.

- New technology increases the feasibility and lowers the cost and complexity of matching/pairing.

- Fleets would consider matching more tractor-trailer by models for savings. A 5% to 10% net improvement in truck operating costs could be sufficient to interest fleets in changing operations to facilitate intentional pairing.

- Large fleets will likely never have 100% of the same model year tractors or trailers because of the partial annual replacement of fleet assets.

- Intentional pairing has potential for a number of vehicle parameters — for example, lightweight tractors paired to lightweight trailers can maximize payload in a tradeoff with service life and gradeability.

More Regional Haul

If you ask most people to define trucking, words like “over the road” and “long haul” are likely to be part of the description. But the reality is that 45% of the Class 8 tractors produced today are day cabs, and a high percentage of those trucks are involved in regional haul operations.

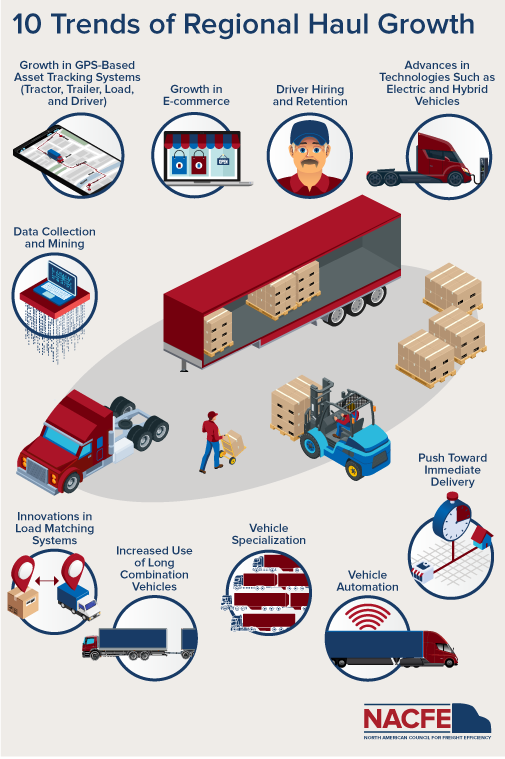

Both outside influences and changes in the trucking industry itself are having an impact on length of haul and the way freight gets delivered. This study looked at the potential of a significant increase to a known but often under recognized segment of the market — Regional Haul.

This report focuses on assessing the current state and future of regional haul as a result of trends in driver retention, growth in e-commerce, the push toward immediate delivery, growth in GPS-based asset tracking systems, advances in technologies such as electric and hybrid vehicles, vehicle automation, and innovations in load matching systems.

Methodologies and Scope

NACFE’s research for this report included interviewing key people with first-hand knowledge of regional operations at fleets, manufacturers, and industry groups. The report includes an extensive list of references to assist readers interested in pursuing more detail. These references were researched with the same diligence and thoughtful processes NACFE uses with its technology Confidence and other Guidance Reports.

This report covers regional haul in Classes 7 and 8 tractor-trailer operations that use vehicles (day cabs or sleepers) with gross vehicle weight ratings (GVWR) greater than 26,000 lbs. Although NACFE recognizes that regional can include a wide range of trailer types such as containers, fuel tankers, grain haulers, milk tankers, chemical tankers, bulk haulers, car haulers, and more, we limit this report to dry vans and refrigerated van trailers in any of a number of configurations as the majority volume is in this segment.

Conclusions and Recommendations

NACFE confirms that there is a growth in regional haul operations versus over the road (OTR) operations driven by a combination of several factors:

- Driver hiring and retention

- Growth in e-commerce

- The push towards immediate delivery

- Growth in GPS based asset tracking systems (tractor, trailer, load and driver)

- Advances in technologies such as electric and hybrid vehicles

- Vehicle automation

- Innovations in load matching systems

- Increased use of long combination vehicles

- Data collection and mining

- Vehicle specialization

The two biggest takeaways from the report revolve around drivers and alternate fueled vehicles. Regional operations means drivers are more likely to get home on a regular basis and that could help the industry with its driver recruitment and retention problem.

Regional operations are also fertile ground for alternate fueled vehicles because by their very nature they make it easier for fueling infrastructure for vehicles that use an energy source other than gasoline or diesel fuel to be installed.

Decision-Making Tools

Regional freight is a proving ground for new technologies, new operational models and business practices. There are a number of trends interacting to define the future of Regional freight hauling. Those trends are:

- Driver hiring and retention

- Growth in e-commerce

- The push towards immediate delivery

- Growth in GPS based asset tracking systems (tractor, trailer, load and driver)

- Advances in technologies such as electric and hybrid vehicles

- Vehicle automation

- Innovations in load matching systems

- Increased use of long combination vehicles

- Data collect and mining

- Vehicle specialization

Determining Efficiency

This report provides a comprehensive overview of the fuel and freight efficiency measurement and estimation methods used by the industry today. This will allow fleets to make better investment decisions, no matter the technology they are considering.

I want access to as much credible information as can be obtained, in order to determine the fuel savings potential for any technology that we may introduce into our fleet.

– Rob Reich, Senior Vice President, Equipment, Maintenance & Driver Development, Schneider National, Inc.

Overview and Test Methods

There are many fuel efficiency technologies available to fleets but no truck could or should have all of them. Fleets must analyze the range of options and compare them against their own operations to determine which offer the fastest payback. To do this, fleets need a solid understanding of their own operation and test data on the performance of various vehicle technologies.

However, it is not possible for fleets to test every device so they must rely on data from other sources. There are a variety of test methods and each has its appropriate application. Understanding what each test method involves, its benefits and challenges, and how it deviates from real world performance will help fleets have a better understanding of how to interpret the data.

OEMs should also conduct tests on the fuel efficiency of various components to help determine which technologies to offer on their vehicles. In addition, providers of technology should invest in testing in order to better develop and validate their designs.

Basic Test Methods

There are many published test methods, but all fall into one of five basic categories:

- Computer Modeling—Computational Fluid Dynamics Analysis This method uses computer software such as facsimile digital geothermal models to calculate a vehicle configuration’s performance. .

- Wind Tunnel Testing Tractor/trailer wind tunnel testing uses a physical scale model of a vehicle (or in some cases a full-sized vehicle) in a wind tunnel where environmental conditions can be controlled. The size of the wind tunnel dictates the size of the model needed.

- Track Testing There are a variety of test protocols for use on a test track. Each attempts to quantify known components of the total performance and infer that what remains is attributed to the device being tested. Assumptions and simplifications can impact test results.

- On-Road Testing This involves evaluating a tractor-trailer on an actual highway over a statistically significant number of miles with an acceptable level of repeatability. It measures the performance of the entire vehicle and all its factors as a net total.

- Fleet Composite Evaluation All fleets perform fleet testing if they record miles driven, freight carried, and fuel purchased. This can validate technology choices when the data is collected and analyzed.

Benefits

Determine How to Prioritize

All the test methods have value in helping to determine how to prioritize technology adoption.

A Starting Point for Technology Investments

Test results provide a starting point for discussion in technology investments.

Challenges

Testing Variance

Variance among testing methods.

Extrapolation

Extrapolation of test results.

Attributing Efficiency Gains

Need to precisely attribute efficiency gains.

Data

Use of older data.

Precision vs. Accuracy

Confusion between precision and accuracy.

Complexity of Calculations

Complexity of calculations and variables measured.

Cost to Benefit Evaluation

There is no one single correct method for fuel economy evaluation. Each method has its costs and complexity. Cost to benefit needs to be considered before purchasing a fuel saving technology.

Case Studies

- Aerodynamics The EPA documented one example of the variation in results from different test methods in its Regulatory Impact Analysis for Phase 1 Greenhouse Gas Rules.

- 6×2 Axles A Trucking Efficiency Confidence Report published in December 2013 on 6×2 axles illustrates the difficulty inherent in comparing directly between test results rather than looking at trends.

Conclusions

- The words accurate and precise are not interchangeable.

- Data is available but needs to be shared.

- The more methods used, the more confidence there is in trends.

- Clarify objectives.

- Adjust to operations.

- Be comfortable with a range.

Recommendations

For Fleets

- Understand scope, context, and constraints of test methods and how results will translate to real-word predictions.

- Understand what factors are being measured, which are assumed, and which are estimated.

- Accurately quantify the fleet’s own current performance.

- Do not seek to determine absolute value for performance payback; instead look at the percent change.

- Look for trends.

For Test Designers and Others Sharing Test Data

- Achieve industry agreement on an absolute reference vehicle.

- Initiate a concerted effort to correlate each test method to this absolute standard.

- Continuously improve and refine measurement methods.

- Share test results throughout the industry.

- Work to provide better information on the potential impacts of real-word factors.