Various Options Exist to Control Idling

Idle reduction is about cost savings and driver comfort. Historically, a large amount of operating time of a sleeper tractor-trailer engine was idling. This could be 45% or more, where the driver is sleeping, eating, working or relaxing in his or her vehicle when they are not driving.

Each year in the United States sleeper tractors burn millions of gallons of diesel fuel while idling. The average truck idles about 1,000 hours a year. This is costly, noisy, dirty and not efficient. A plethora of idle-reduction solutions have emerged including on-board diesel and battery units, engine start/stop, diesel heaters and driver training and incentives to drastically lower idling. Each, along with other complementary actions, have their benefits and challenges with respect to fuel and emissions reductions, upfront cost, maintenance costs, infrastructure, etc.

Idle Reduction Technologies

Fleet Survey Results

- If a fleet does not use APUs, their idle percent tends to be in the 30% to 50% range

- If a fleet uses APUs, idle percent is in the single digits to 20%

- Fleets seem to be split on diesel APUs vs. battery HVAC systems with some fleets using both (but not on a single vehicle)

- Use of auto start-stop systems is increasing

- Almost everyone uses diesel fired heaters

- Most fleets are looking for positive ROI, but most of them also think there is significant value in driver retention and hiring

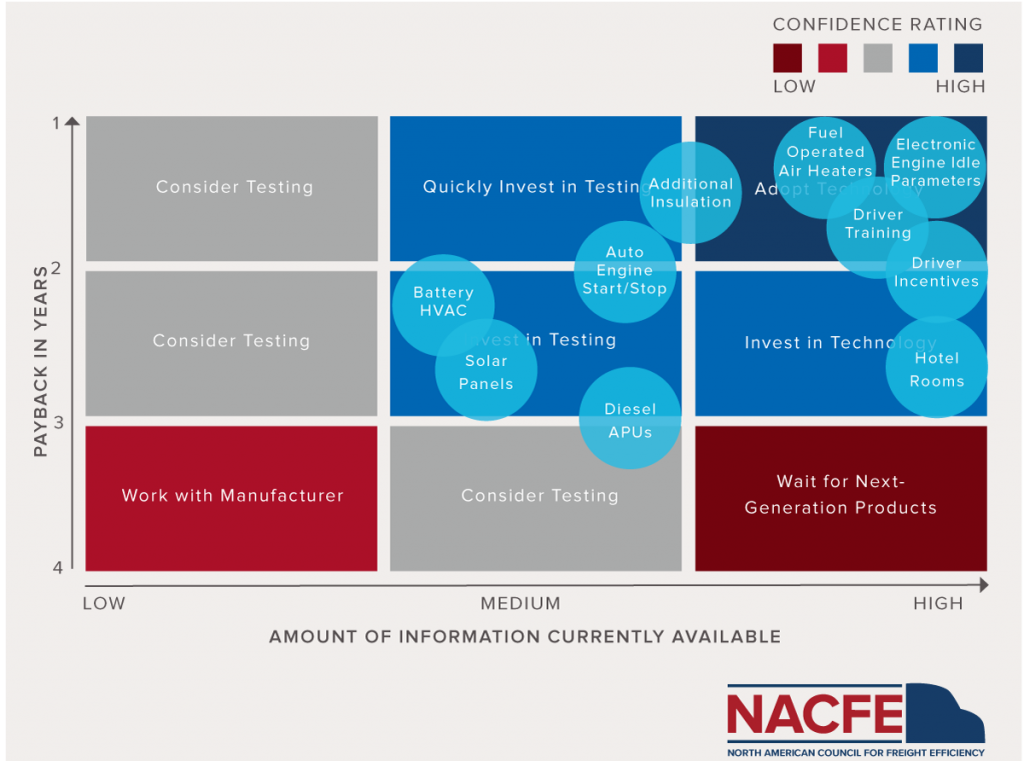

Decision-Making Tools

Our team produced top-line tools to assist fleets in making their idle-reduction technology choice. The Confidence Matrix summarizes the study findings and indicates NACFE’s confidence in the various idle-reduction technology solutions. In addition, the report contains challenges and changes charts for each of the anchor technologies. The charts can be found in section 9 of the report.

Conclusions

As a result of research and interviews the study team reached the following conclusions concerning idle reduction in the sleeper cab market:

- Reducing idle is good for the environment, saves fuel and improves a fleet’s “green” image.

- A 10% reduction in annualized idle percentage is worth about 1% in fuel economy that results in a $500 to $700 annual savings assuming 100,000 miles a year and diesel at $3 a gallon.

- Driver hiring, comfort and retention are mentioned in almost every conversation about idle-reduction technologies. Some have said that offering a good solution is a requirement for hiring and retaining drivers.

- There is no “one size fits all” solution to idle reduction.

- Drivers are still a very important part (If not the most important part) of successful management of idle times.

- Depending on “shore power” (outside electrical connection) to be available is not a reasonable idle-reduction solution for most fleets as the number of electrified parking spaces is extremely small compared to the number of trucks that need to be parked at any given time.

- Most suppliers of idle-reduction technologies mention that their solution helps minimize maintenance costs, particularly in the vehicle’s aftertreatment system. However, we have been unable to uncover any data that actually substantiates those claims.

- The answer to the question of the resale value of trucks equipped with idle-reduction technology is unclear.

- Maintenance of the vehicle’s battery connections and electrical systems is critical to getting the best performance out of idle-reduction technologies.

Battery HVAC

Battery-powered heating, ventilation, and air conditioning (HVAC) systems help fleets deal with cab climate control, by providing climate control to the truck cabin while the truck is parked. Fleet users benefit because the systems are quiet and produce no emissions, but they may not provide enough cooling capacity for long rest periods or when operating in very hot temperatures.

They can be powered by a set of batteries on the tractor or come with a plug-in capability for battery charging and/or operation while connected to an electrical power source. They are also called battery APUs and battery EPUs.

Benefits

Zero Emissions

No emissions produced during operation

Fuel Cost Reduction

Since they do not burn fuel there is no fuel cost while they are in use.

Lower Purchase Price

Less expensive than some other anti-idling options.

Quiet Operation

Quieter than diesel APUs.

Less Maintenance

Fewer moving parts so less opportunity for malfunction and less maintenance training than diesel APUs.

Integrate with Off-board AC Power Connection

This will increase the operating time of the unit and will also recharge the batteries more cheaply than doing so with the engine alternator.

Easy to Operate

Digital or rotational automotive-style controls provide automatic temperature control. The driver simply turns the switch to heating or air conditioning, and selects a fan speed and a desired temperature.

Challenges

Limited Run Time

Not a viable solution for the 34 consecutive hours of rest without restarting the truck’s main engine and running it from time to time. In most cases, however, the batteries of the battery HVAC system will simply be recharged while the truck is driving.

Issues in Hot Temperatures

Concern that in extremely hot conditions there will not be enough battery power to keep the sleeper/cab cool enough for the driver to be comfortable.

Battery Replacement

The AGM batteries in these units do not last forever and will have to be replaced. Two years seems to be the typical life expectancy of these batteries.

Added Weight

Including the required four deep-cycle AGM batteries and a fuel-fired bunk heater, battery HVACs will add 500 to 600 lbs. to the weight of the vehicle. This may become less of an issue in the future if other battery technology is developed. However, the Energy Policy Act of 2005 allowed for a national 400-pound exemption for the additional weight of idling reduction technologies on heavy-duty vehicles. In 2012 the Moving Ahead for Progress in the 21st Century Act increased the weight allowance to 550 lbs. However, each state can adopt the exemption at its own discretion and not all states have. The Office of Energy Efficiency & Renewable Energy has a map showing states that recognize the APU weight exception.

Need for Large Capacity Alternator

The increased load battery HVACs place on the charging system means a large capacity alternator is needed. Cables of the proper size also must be used, and it is important that all connections be tightened properly for the system to operate.

Adds Load to the Engine

The alternator for a battery HVAC system puts twice the load on the engine of a normal sleeper tractor’s alternator. These higher capacity alternators take up to an additional 7 hp from the engine. Therefore, their use does cause a truck to consume slightly more diesel fuel while driving, but lowers fuel use overall as they can eliminate significant amounts of idling.

Can Consume Fuel

Systems equipped with fuel-operated heaters will consume diesel fuel during heater operation as well as battery or AC power to run the heater fan.

To learn more, download the Idle Reduction Confidence Report.

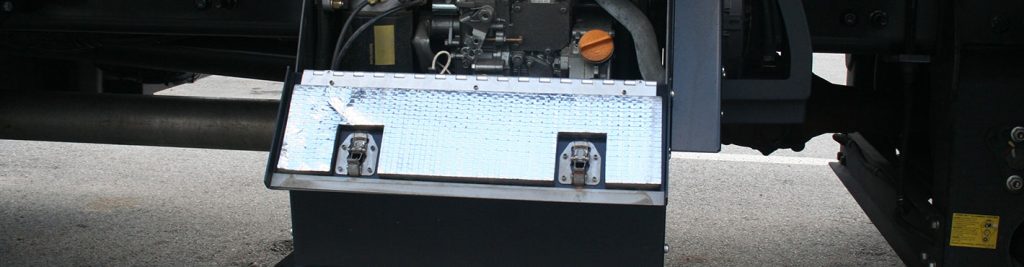

Diesel APUs

Diesel APUs can provide cooling, heating, and electrical power to the sleeper cab while the truck’s engine is off. Some diesel APUs on the market today provide heating, bunk cooling and AC power for hotel loads, while others provide bunk cooling and AC power only and then also use a fuel-operated air heater for cab heat. All diesel APUs also charge truck batteries and can provide electrical power for a block heater if the engine is so equipped.

They generally burn between 0.1 and 0.5 gallons of fuel per hour depending on their design, the ambient temperature, the sleeper’s insulation, and the resulting HVAC load, along with the AC power being generated.

Benefits

Complete Solutions

Provide cab cooling, heating, AC power for hotel loads, and battery charging.

Long Operating Time

Can operate as long as the truck has fuel. This provides nearly an unlimited amount of time for cooling, heating, and AC power without the need to restart the truck engine. Battery HVAC systems are limited in the hours of cooling they can provide before truck engine restart and battery recharging is required. Also, their hotel load AC power capabilities usually are less than that of their diesel-powered counterparts.

Suited for Temperature Extremes

High Btu capacity allows operation in extreme temperatures. Colder weather reduces battery capacity thus negatively affecting hotel load AC power capabilities of battery HVAC systems, while diesel APUs can avoid those issues.

Challenges

Purchase Price

Expensive to purchase, install and maintain compared to other idle-reduction technologies. Compared to battery HVACs, for example, diesel APUs require periodic oil and filter changes and have more parts and components to be maintained. A typical service interval for a diesel APU is every 6 to 12 months. With a battery HVAC system, batteries need to be changed approximately every 2 years unless and engine start/stop system is employed to keep the batteries from being discharged too often. It is likely that while diesel APUs need maintenance on a more frequent basis, the cost of that maintenance will be equal to or less than the cost of replacing batteries on battery HVAC systems.

Installation Issues

Due to their mounting location, diesel APUs are exposed to road debris, salt and spray, and need adequate frame space to be installed. Additional work is required at installation for an open-loop system.

Consume Fuel

Need diesel fuel to operate and generate emissions and noise, while reducing fuel savings less than other idle-reduction technologies.

Don’t Meet Zoning Restrictions

Urban municipalities have zoning restrictions prohibiting the use of diesel APU. In California, for example, a fleet may need to add an expensive DPF to make a diesel APU compliant with that state’s specific emissions regulations. With the upcoming Greenhouse Gas Phase 2 regulations, the emissions regulations on diesel APUs are likely going to get tighter.

Add Weight to Vehicles

Diesel APUs weigh between 450 and 550 lbs. when installed. In addition, you have to add another 20 pounds for fluids. However the Energy Policy Act of 2005 allowed for a national 400-pound exemption for the additional weight of idle-reduction technologies on heavy-duty vehicles. In 2012 the Moving Ahead for Progress in the 21st Century Act increased the weight allowance to 550 lbs. However, each state can adopt the exemption at its own discretion and not all states have done so. The Office of Energy Efficiency & Renewable Energy has a map showing states that recognize the APU weight exemption.

To learn more, download the Idle Reduction Confidence Report.

Automatic Engine Start/Stop

Automatic engine start/stop systems start and stop the main diesel engine in an unattended fashion to provide a variety of features without requiring the truck’s engine to idle continuously. These systems have a set of inputs to ensure that it is safe to start the engine without anyone at the controls.

They provide some key features:

- Heating and/or cooling the sleeper bunk while drivers are on a rest period

- Maintaining adequate battery charge so the engine will start easily when the rest period is over

- Maintaining engine coolant temperature so the engine will start easily when the rest period is over

There are two different types of automatic engine start/stop systems. The first has a primary goal of maintaining a cab’s interior temperature when the vehicle is occupied. These may also assist with keeping the engine warm and the batteries charged. The second type of automatic engine start/stop system focuses solely on maintaining the batteries’ state of charge.

Benefits

Little Added Componentry

They do not require additional HVAC components, batteries, or engines to accomplish their tasks.

Can Be Combined with Other Technologies

It is becoming increasingly common to pair an engine start/stop system with a battery HVAC system. This allows the engine to start automatically without driver input when necessary to keep the batteries charged and keep the battery HVAC system from shutting off if it runs low on available power.

Can Avoid Violating Idle Regulations

If a vehicle is purchased with a CARB Clean Idle engine, it will have a serial numbered holographic sticker on the driver’s side of the hood or driver’s door. Such stickers allow automatic engine start/stop systems to be used without violating any idling regulations, provided that the vehicle wasn’t also purchased with the tamper-proof five-minute timer.

Challenges

Can Interrupt Driver Sleep

Noise and vibration of the system starting and stopping can disturb drivers. Drivers did not like the initial automatic engine start/stop systems that came out about two decades ago because when those systems started and stopped the main engine the noise and vibration was enough to wake a sleeping driver. Newer systems have made improvements, such as using the engine brake to create a more rapid and smooth engine shut-off than the cab rocking and engine sputtering which occurs during a normal engine shut down. If there is a large temperature difference between the desired bunk temperature and the outside temperature, the engine starts can become fairly frequent, exacerbating the sleep interruption problem. Another concern is the alarms that may go off as part of the engine starting process. The system manufacturers offer features to suppress these alarms when the start/stop system is enabled.

Required Main Engine to Idle

Creates additional hours of wear on the main engine.

Issues with Idle Law

It is not completely clear how various idle laws relate to some of the operational modes available with these systems. Refer to the resources listed in section 5.6 for the latest information on idling regulations.

To learn more, download the Idle Reduction Confidence Report.

Fuel-Operated / Diesel-Fired Heaters

Fuel-operated or diesel-fired heaters use diesel fuel to provide heat to the sleeper cab (bunk or air heaters) or to provide heat to the truck engine (water or coolant heaters). Both types of heaters can operate when the truck’s engine is off, therefore avoiding idling. However, these systems do not provide any cooling or AC electric power to the cab. There are two types of fuel-operated/diesel-fired heaters:

- Fuel-operated air heaters

- Fuel-operated coolant heaters

Benefits

Cost

Relatively inexpensive to purchase and maintain.

Fuel Efficiency

Generally burn less than 0.1 gallons of fuel per hour. An idling diesel engine will consume between 0.6 to 1 gallon of fuel per hour. On average a fuel-operated air heater will use approximately a gallon of fuel during a 24-hour period.

Easy to Install

Install easily usually under or behind the sleeper, do not require frame free space. Available as factory installed options from all truck OEMs. Integrate with other idle-reduction technologies, and are often sold in combination with other idle-reduction technologies.

Reduced Noise and Emissions

They operate very quietly and produce minimal emissions.

Vehicle Performance Enhancements

Eliminate difficult truck engine cold starts. Pre-warmed engines deliver cab heat and defrost windows more quickly upon engine start up, and warm engines produce fewer engine emissions at start-up.

No Electrical Connection Required

Provide higher heating capacity than engine block heaters and do not requite AC power electrical connections.

Easy to Use

Can be programmed for remote start-up without driver interface.

Factory Installed

Available as a factory-installed options from all truck OEMs.

Challenges

Limited Functionality

Only provide bunk heat and do not meet the other driver needs — air conditioning or AC power for hotel loads — nor do they provide engine pre-heat.

Affect Battery State of Charge

Use the truck’s main engine batteries for their power, and therefore can drain those batteries over long periods of use.

Emissions

Emit some exhaust as they burn fuel.

To learn more, download the Idle Reduction Confidence Report.

Solar Panels – Tractors

Interest in solar panels is growing among fleet managers because the main truck batteries are often no longer able to meet the power needs of today’s trucks due to increased driver comfort demands, and new idle-reduction legislation.

Solar panels designed for the trucking industry are almost all flexible, thin, lightweight, and capable of being affixed to the curves of a tractor fairing.

The main use of solar on tractors is to support battery HVAC systems and hotel loads without batteries. Solar panels can extend the runtime of battery HVAC systems, not only to help the HVAC system make it through the night without draining the truck’s batteries, but also to reduce the load on the alternator the next morning, resulting in fuel savings. Solar panels can augment the energy coming from the truck batteries and maintain the batteries at a higher state of charge extending the battery life and increasing driver comfort by allowing hotel loads to operate for longer periods of time.

Available Systems

Although solar is relatively new, two of the seven tractors in NACFE’s 2017 Run on Less demonstration already had solar panels on the tractor and an additional vehicle had solar panels on its dedicated trailer. The latest generation of solar panels are flexible and have the wiring on the underside to make them more capable of being installed on the curved surfaces of a tractor with good durability.

Benefits

Idle Reduction

If the solar system can minimize engine idling while parked, all of that fuel savings goes directly to the payback of the solar system. A Battery HVAC system pairs well with solar systems.

Jump-Start Reduction

Solar can minimize the needs for roadside assistance calls for jump starts. When the truck is down for service or other needs, it is not unusual for refrigerators and other hotel loads to drain a battery. The use of solar to keep the batteries charged can reduce the expense and inconvenience of jump-starts and therefore unplanned downtime.

Fuel Economy

Direct benefits are fairly minor, but solar panels can assist in keeping batteries charged especially when the engine is turned off.

Battery Life

Keeping a proper state of charge may extend the life of a tractor’s main or auxiliary batteries.

Driver Convenience

Solar can allow the refrigerator to remain on when the truck is not in use. This can be especially valuable to drivers to eliminate unloading and reloading the refrigerator during resets and weekends. Solar can also allow drivers to run some hotel loads, including battery HVAC systems, without idling during rest periods.

Driver Retention & Recruiting

The advantages of using solar power to keep refrigerators running and avoiding downtime (and therefore lost miles) waiting for jump starts can be valuable in keeping and finding new drivers. Solar and battery HVAC systems together can minimize engine idle time and therefore increase driver bonus opportunities.

Challenges

Cost and Installation

The aerodynamic curvature of the sleeper roof can be a limiting factor in mounting solar panels, though flexible panels are available for this purpose.

Sun Exposure

With the shortage of available tractor-trailer parking, it is difficult to ensure that the solar panels can face directly into the most intense sun exposure. Latitude directly ties to the angle of the sun and length of solar exposure as well. Cloud levels vary by geographical regions so results with solar panels will definitely vary.

Cleanliness

Dust, dirt and snow can reduce the solar conversion effectiveness. Check out stories of the Mars rover to see dust in the most extreme environments. The coatings on most panels minimize this issue.

Trade Cycle and Residual Value

The use of solar panels on tractors is too new and too low in penetration to determine the residual value at this time. Unfortunately it is also not easy to port the system from a current vehicle to a new vehicle.

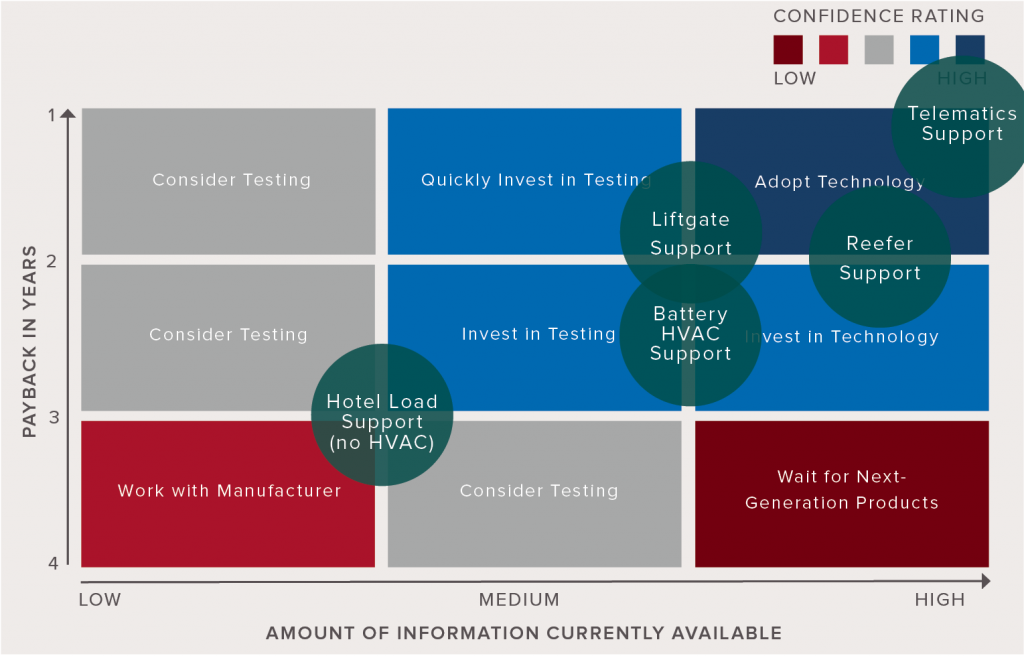

Decision Making Tools

The study team developed several tools to help fleets in making their decision about solar panels. The confidence matrix is used to inform fleets of the study team’s confidence in the technology being studied vs. the payback a fleet should expect to receive from the technology.

Conclusions

- Solar technology for trucks has progressed to the point where the panels on the market are flexible, thin, easily installed and reliable. Some use cases are an excellent application of the technology and should be strongly considered for future purchases, while for other applications the cost vs. benefits should be evaluated to see if it makes sense in the specific application.

- Fuel savings are generally a very small part of the overall benefit that comes from a solar panel installation.

- Solar panel installations need to be sized appropriately for their intended application.

- There is limited hard evidence at this point from fleets that the payback from the investment in solar panels matches that claimed by the solar panel suppliers. Benefits fall in several categories with the biggest benefits being from extending battery life and avoiding emergency roadside assistance for dead batteries.

Future Perspective

The field of solar as applied to trucks is a constantly and rapidly evolving one. The future might lead to improved technologies, cost reductions, more electrification of trucking loads, and extended trade cycles, all of which would make solar systems even more attractive and cost-effective for fleets.

Electronic Engine Idle Parameters

Electronic engine parameters can be set to limit the amount of main engine idling. These can include controls that cause idle shutdown after three to five minutes, or based on ambient air temperature.

Electronic engines allow fleets to set parameters in a wide variety of areas. These parameters can control the exact speed for idling the engine, set the idle timer length and establish the boundaries of when idling is allowed in both hot and cold temperatures. Parameter names vary by engine maker. Typical fleet temperature limits were 75°F as an upper limit and between -10°F and 25°F on the lower limit.

Benefits

Standard Equipment

Electronic engines are standard equipment and come with no additional cost.

Custom Fit

Parameters can be adjusted to fleet’s specific needs.

Complementary

Electronic engine idle parameters can complement other idle-reduction technologies.

Challenges

Modification by Unauthorized Personnel

Parameters can be modified by unauthorized personnel, and therefore not reliably set at the optimal parameters.

Common Fleet Strategies

Some fleets are pursuing idle-reduction strategies that allow them to make only a minimal investment in technology coupled with a larger investment in driver engagement. This strategy is based on using a fuel-operated air heater for cold support and employing electronic engine idle parameters such as ambient air shutdown, and then training drivers and providing them incentives to engage in behavior that limits idling. All four of these technologies must be used in concert to be an effective idle-reduction strategy.

What People Are Saying

Executives from 11 for-hire truckload carriers were personally interviewed to find out about their idle-reduction practices. No single technology was used by all 11 of the fleets, but eight indicated they use electronic engine parameters as part of their idle-reduction strategy. One interesting note: some fleets did not know how the vehicle controlled idle shut down, which could mean they do not consider electronic engine parameters as part of idle reduction. Some wondered why the study team was asking about electronic engine

– Large Fleets

In conjunction with Michelin, the study team surveyed 200+ members of Michelin’s Fleet Forum. When asked what idle reduction technology they would purchase, 33.3% said electronic engine parameters.

– Internet Fleet Survey

In conjunction with Kevin Rutherford’s “Let’s Talk” truckers’ satellite radio forum, the study team surveyed owner-operators and small fleets. Electronic engine controls ranked low on the list of technologies these survey respondents would include in a new truck specification, this could be based on lack of awareness that there are engine parameter settings available to allow idle to be controlled.

– Internet Owner-Operator Survey

To learn more, download the Idle Reduction Confidence Report.

Additional Idle Solutions

The report identified technologies that fleets can use to reduce engine idling:

- Automatic engine start/stop start systems

- Battery HVAC systems

- Diesel APUs

- Fuel-Operated/Diesel-Fired Heaters

However there are number of ancillary technologies that can be beneficial to a fleet’s idle-reduction efforts. Most of these sleeper tractor additions are passive, and can be used in conjunction with other active idle-reduction systems, to achieve even better levels of idle reduction.

They include:

- Additional cab insulation decreases the energy demanded by the heating and cooling systems. Insulated bunk curtains, windshield curtains, and extra insulation are options.

- Light-colored paint helps reduce the heat loading of the sun on interior of the vehicle. A black vehicle requires 26.3% more energy to cool on a sunny summer day than the same baseline vehicle painted white.

- Auxiliary CPAP battery powers a CPAP machine through the night, which can help relieve the truck’s batteries from having to power the machine.

- Ultracapacitor starting system can alleviate the strain on discharged batteries and help start the engine. The system can store energy and deliver power.

- Sleeping quarters, such as hotels or dormitories, may be the most radical method of reducing idling by getting the driver out of the vehicle altogether for the HOS restart period.

- Truck Stop Electrification is similar to hookups at RV parks and allows trucks to power everything drivers need from an external power source. Some systems require special wiring and equipment. Others provide everything through a console that fits through the window frame.

- Off-board AC power systems (also known as shore power) combine elements of both vehicle and truck stop electrification as they require both AC wiring and power ports to be installed inside the sleeper as well as infrastructure to be deployed for an external AC power source.

- Solar panels can augment the amount of power generated by the alternator, but they are especially useful for charging the battery HVAC system to allow longer running time. And to help prevent hotel loads from draining the batteries.