Upfits & Retrofits

While much of NACFE’s information focuses on the “what”, to implement these solutions can require a lot of work on the “how” to make the transition to a new vehicle feature. If a feature is not offered on the vehicle configuration that you desire, there are other ways to obtain the desired product.

Features can be “upfit” at a customization center immediately after initial production. It is also common to “retrofit” a feature to a vehicle after it is in service. This is especially true when it comes to the addition of trailer skirts or automatic tire inflation systems on trailers.

Benefits

Fuel Economy

If a new feature shows promise and has a good ROI for your fleet, getting it installed across the fleet will have a multiplicative impact on the results.

Standardization

Having all vehicles equipped similarly will make it easier for your technicians and training department, and also level the playing field for driver performance and driver pay bonuses.

Staff Workload

Many fleets are in a situation where their technicians are at full capacity or near that point. Taking on additional work to retrofit a new feature interrupts critical day-to-day operations. Post production line installs or on-site upfit specialists can alleviate these challenges.

Challenges

Warranty Coverage

Depending on who and how an item is installed, it may not have warranty coverage and in the absolute worst case, an improper installation could invalidate the warranty coverage for other parts of the vehicle.

Service & Parts Support

Don’t expect the OEM and dealerships to support something that they don’t yet have in production. Be ready with alternative plans to support your customized features on the road.

Introduction & Rationale

Although most OEMs have extensive product offerings, there are so many different technical solutions it isn’t practical for them to offer all features in combination with all other features. If your preferred combination is one that isn’t offered, isn’t yet validated for factory installation, or simply isn’t high volume yet, there are alternative ways to get a component, part or device installed.

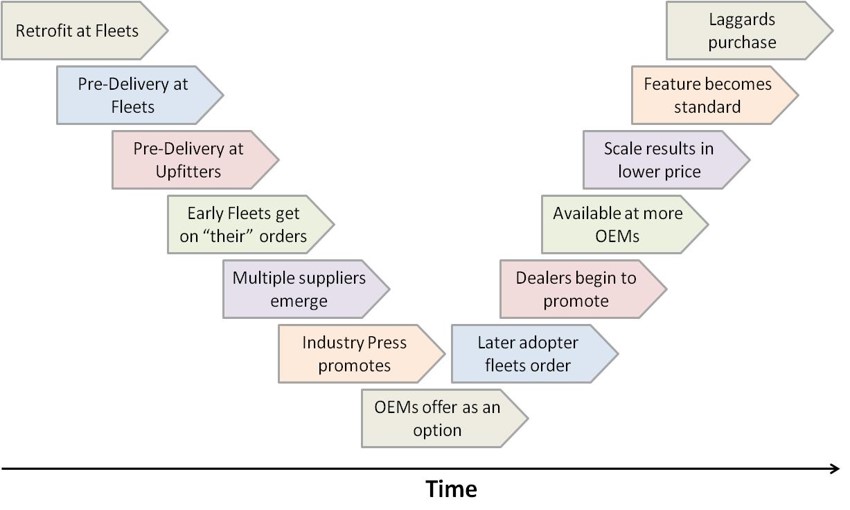

NACFE’s Collaboration Report ICCT Barriers to Adoption found that “lack of access to technologies” was one of the common barriers to the adoption of fuel efficiency technology. The barriers report illustration below shows how new features commonly work their way into the commercial vehicle marketplace in North America. Upfits and retrofits are additional avenues to gain access to features a fleet desires.

Available Systems

Many production assembly plants have nearby facilities that can accommodate features that are not available on the main production line. These facilities go by many different names with some being owned by the OEM themselves, while others are owned by independent sources.

There are also companies that specialize in making upfits in the field. This takes the burden off the fleet’s own shop staff and allows them to continue performing their existing assignments without being disrupted by retrofitting new features to older vehicles. These outside organizations are likely to have more experience with upfits than a fleet and therefore would be faster and more efficient at completing a quality installation.